Morphological evolution and grain size distribution of as-cast and solution treated Cu-Zn-Al alloy

Keywords:

Shape memory alloy, Grain size, Solution treatment, Cu-Zn-Al alloys, Martensitic transformation, microstructure.Abstract

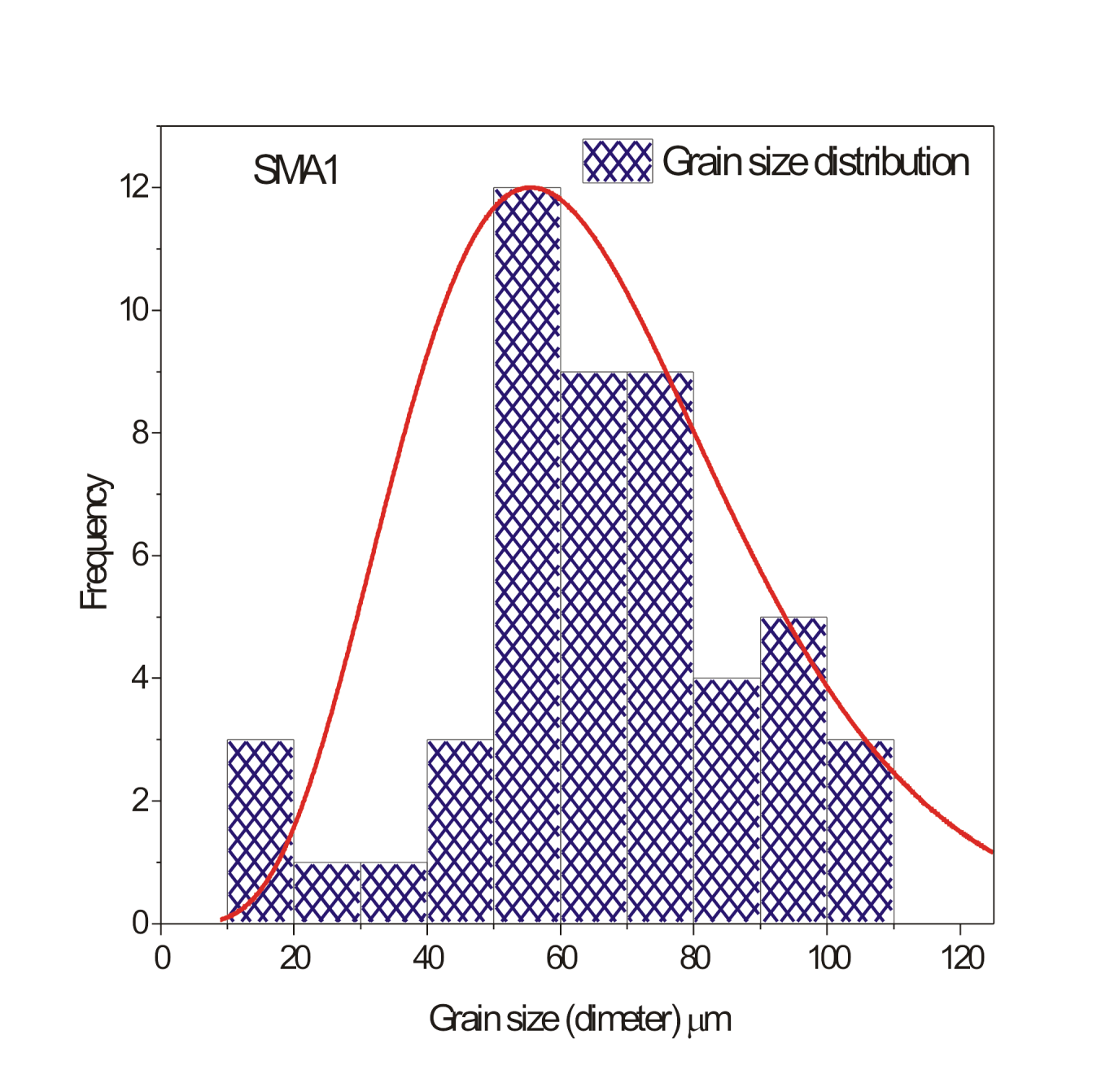

The development of ternary Cu-20Zn-6Al shape memory alloys was carried out using an oil-fired crucible furnace for casting. The experimental alloy's chemical, morphological, and grain size distributions were studied in both the as-cast and solution-treated states. The alloy's microstructure was observed and examined using optical metallurgical microscope; it revealed that solution treatment greatly refines and homogenizes the grains. Single martensite phase could be seen in optical micrographs of the as-cast ternary Cu-20Zn-6Al alloy. The martensitic phases required for the shape memory effect are present in both the as-cast and quenched alloys. The as-cast Cu-20Zn-6Al SMA has a grain size distribution of 10 to 110 μm, whereas the solution-treated Cu-20Zn-6Al alloy has a grain size distribution of 60 to 150 μm. Thermal processing and the holding interval before quenching was adduced to have encouraged the observed rapid grain development. Because of the anticipated improvement in mechanical and shape memory qualities as a result of the significant purification and homogeneity of grains observed after solution treatment, the produced alloys may be used in structural vibration damping applications