Tensile behaviour of (3-Aminopropyl) trimethoxysilane and (3-Glycidyloxypropyl) trimethoxysilane treated coir for composites applications

Keywords:

Coir fibre, tensile strength, (3-Aminopropyl) trimethoxysilane, (3-Glycidyloxypropyl) trimethoxysilane, Weibull modulusAbstract

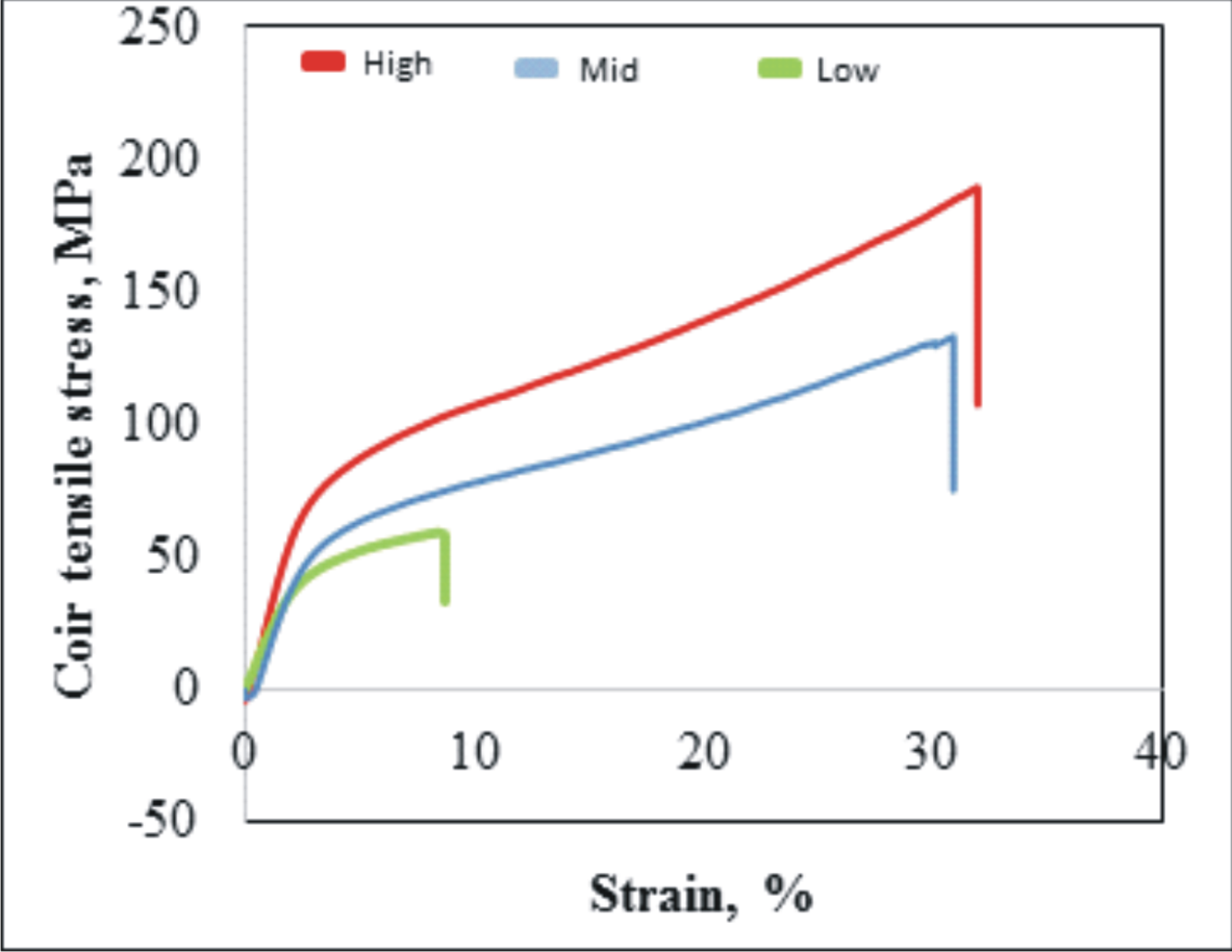

The tensile properties of as-received coir treated using 0.25% (3-Glycidyloxypropyl) trimethoxysilane and those treated with 0.25% of (3-Aminopropyl) trimethoxysilane have been investigated and compared. The tensile strength, Young’s modulus and elongation at break of (3-Glycidyloxypropyl) trimethoxysilane treated coir were; 133.29 MPa, 1.94GPa, and 32.52% respectively; corresponding to 5%, 8% and 15% respectively higher than those of (3-Aminopropyl) trimethoxysilane treated coir fibres. The Weibull modulus of the fibres treated with (3-Glycidyloxypropyl) trimethoxysilane and (3-Aminopropyl) were 4.30 and 3.08 respectively, this means 28% higher than the Weibull modulus of the 3-(Aminopropyl) trimethoxysilane treated coir fibres. The Weibull shape parameters of the treated fibres show lower probability of failure than the untreated fibres from literature. The failure traces show an initial linear region followed by a non-linear region before fracture occurred, typical of natural fibres. The microstructure of the silane treated coir fibre exhibited rough surfaces which might bring about enhanced interlocking of the fibres/matrix and improved interfacial bond strength between the fibre and the matrix during composites manufacture and subsequently, improved mechanical properties of the composites.