Development of an IoT-based real-time remote monitoring device for the maintenance of injection moulding machines in plastic industries

Keywords:

intelligent system, remote monitoring, data, real-time, sensors, parameters, failure prediction, injection moulding machine.Abstract

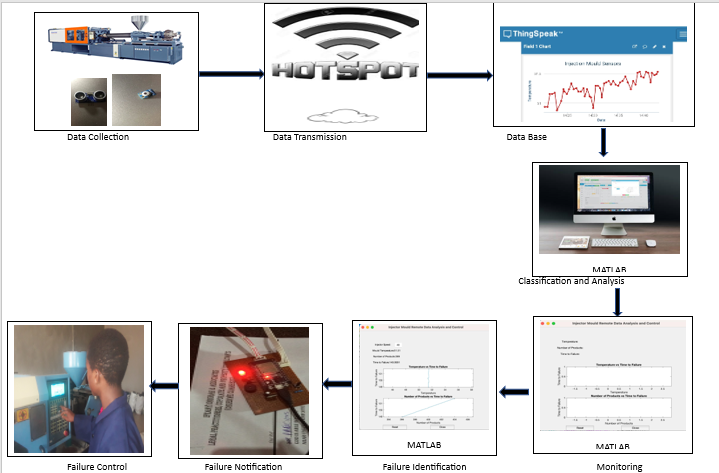

The remote monitoring of industrial equipment for real-time predictive maintenance reduces downtimes and losses brought on by unforeseen failures. An IoT-Based intelligent system developed for real-time remote monitoring and failure prediction of process parameters in the Injection Moulding Machine is presented in this work. The developed system captures data from the equipment, analyses, and transmits the data to the ThingSpeak IoT web server for further fault prediction analysis in MATLAB, with subsequent feedback to users - all in real-time. The software component of the system is developed using MINITAB, MATLAB, ThingSpeak IoT platform, and C++ in Arduino Integrated Development Environment. The hardware component of the system is developed using MLX90614 infrared temperature sensor, ultrasonic proximity sensor HC-SR04, and wifi-enabled Esp32 WROOM-32 Microprocessor. When implemented on the injection moulding machine, the system achieved real-time data capture, analysis, and feedback through its easy-to-understand user interface. Comparative analysis of the developed system’s measured data with that of the traditional method, showed a Pearson Correlation Coefficient of 0.995242, indicating a perfectly positive correlation and consistency of measured data. The system may be beneficial to plastic manufacturing industries for reliable remote monitoring and failure prediction of the process parameters of Injection Moulding Machines towards achieving reduced maintenance cost, downtime, and cost of re-work.