Elastic-Characteristics of Recycled Low-Density-Polyethylene-Date Palm Wood Composite by Response Surface Methodology Optimization Process for Structural Application

Keywords:

Response Surface Methodology, mechanical properties, recycle plastics, Date palm wood, r-LDPE-DPW compositeAbstract

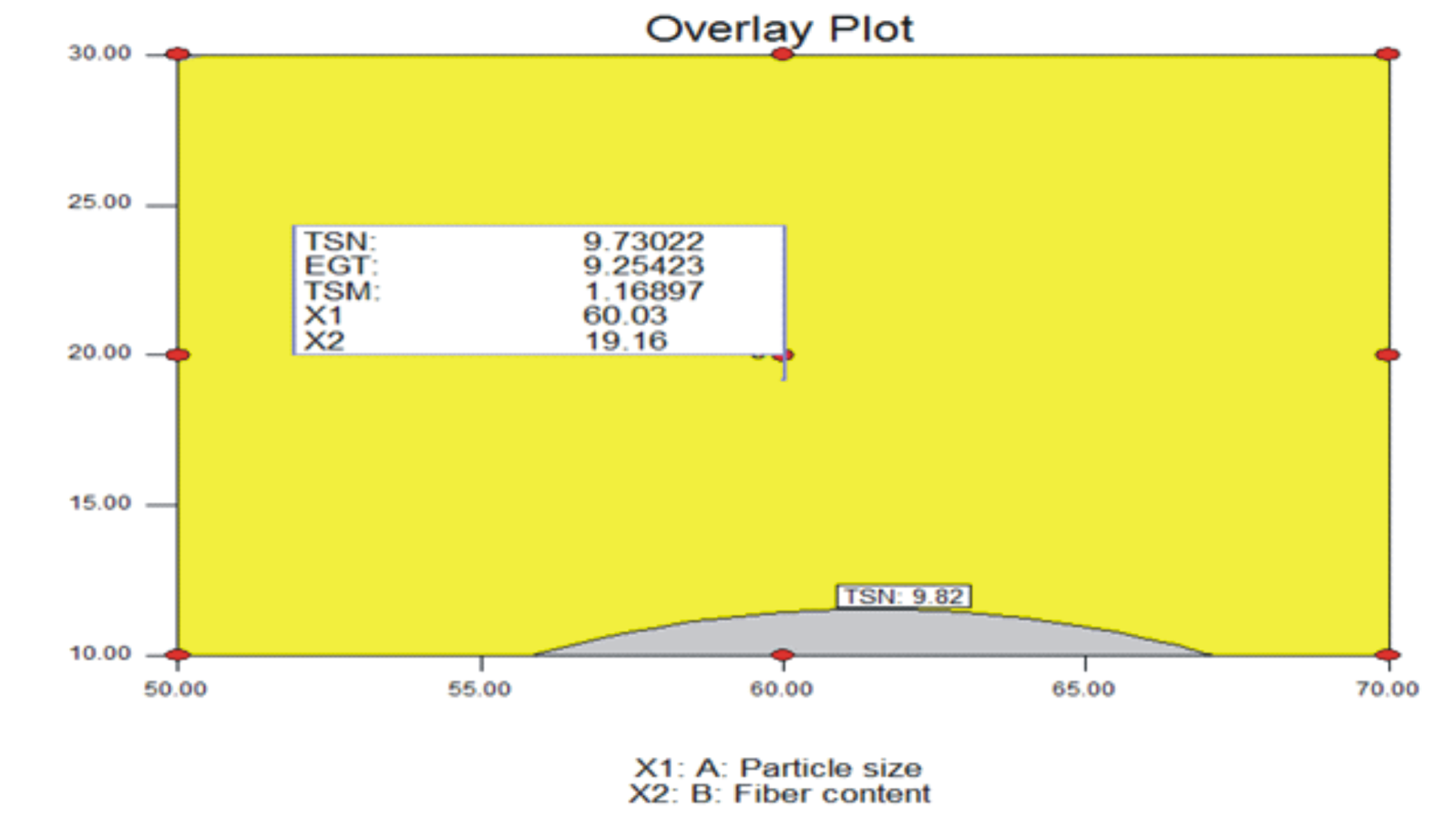

The request for utilization inexpensive plant from non-digestible agro-fiber and non-biodegradable waste from plastics in polymer composite are rudiment of zero deposition of refuse, wealth generation and eco-friendly environment. This work is aimed to optimize the mechanical properties of recycled low-density-polyethylene-date palm wood (r-LDPE-DPW) composite by considering two main process variables; particle size (PS) and fiber content (FC) for automobile parts production. The date palm wood (DPW) was introduced into the powdered recycled-low-density-polyethylene (r-LDPE) at fiber content (10-30 wt%) and particle size of (50-70 mesh no (300-212 µm)) for optimization of the produced composite properties for its eligibility to produce low cost car parts from dispose waste of r-LDPE and ready available DPW. The r-LDPE-DPW composite compounded at this condition was subjected to tensile test to determine the elastic properties using response methodology (RSM). The compounding of DPW and r-LDPE applied through injection moulding machine. The involvement of RSM was employed for its prediction and optimum condition of elastic characteristics of r-LDPE-DPW composite. The properties of r-LDPE-DPW composite studied were tensile strength (TSN), elongation (EGT) and tensile modulus (TSM). The result shows that at optimal state, the PS, FC, TSN and EGT were 60.034 mesh (250 µm), 19.16%, 9.7302 MPa, 9.2545 % and 1.1689 GPa, respectively. The coefficients of determination (R2) and the error for the predicted results by RSM compared to real values obtained experimentally were close to 1 and less than 0.112%, respectively. From the values forecast by RSM, the r-LDPE-DPW composite would be a possible material for production of engineering components for car parts.