Evaluating the Effect of Carbon Black and Silica Hybrid Reinforcement on the Rheological Behavior, Rebound Resilience, Tensile Properties and Tear Strength of Solid Tire Tread Compound Containing Ground Tire Rubber

Keywords:

Tire tread, recycling, hybrid filler, ground tire rubber, propertiesAbstract

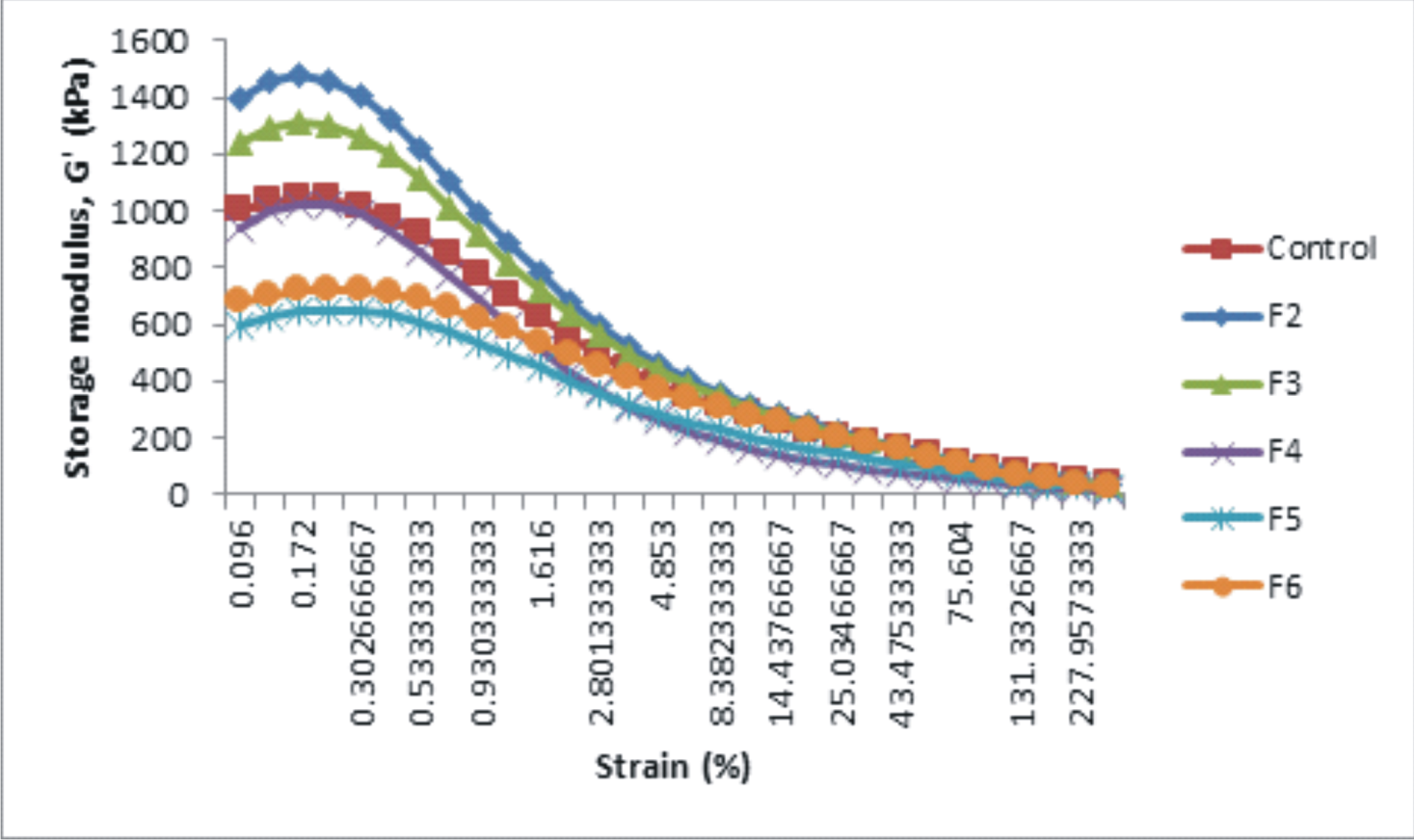

The generation of waste rubber and their disposal to the environment pose serious environmental problems. Researchers have shown interest in the incorporation of ground tire rubber (GTR) into rubber vulcanizates. The major challenge is that the addition of GTR in rubber vulcaniztaes reduces the strength and elongation of the vulcanizate. This work investigates effect of addition of precipitated silica to solid tire tread compound containing 10 phr and 20 phr of 60 mesh size GTR on the cure behavior, Mooney viscosity and Payne effect of the rubber compounds, and the tensile properties of the vulcanizates. The GTR and precipitated silica were initially characterized using optical microscope and particle size analyzer, while thermogravimetric analyzer was further used to characterize the GTR. In the formulation of the tire tread compound, silica was added at 5, 10 and 15 phr together with carbon black at 55, 50 and 45 phr respectively. The mixing followed two-step process. Results show that the 60 mesh size GTR particles were irregular and composed majorly natural rubber, synthetic rubber, fillers and additives. The silica aggregates were roughly spherical. The addition GTR in the rubber compounds resulted to increased viscosity, high Payne effect, reduced tensile strength, elongation, tear strength, rebound resilience and increased modulus. The optimal amount of silica found to achieve improved properties was 10 phr together with 50 phr of carbon black.