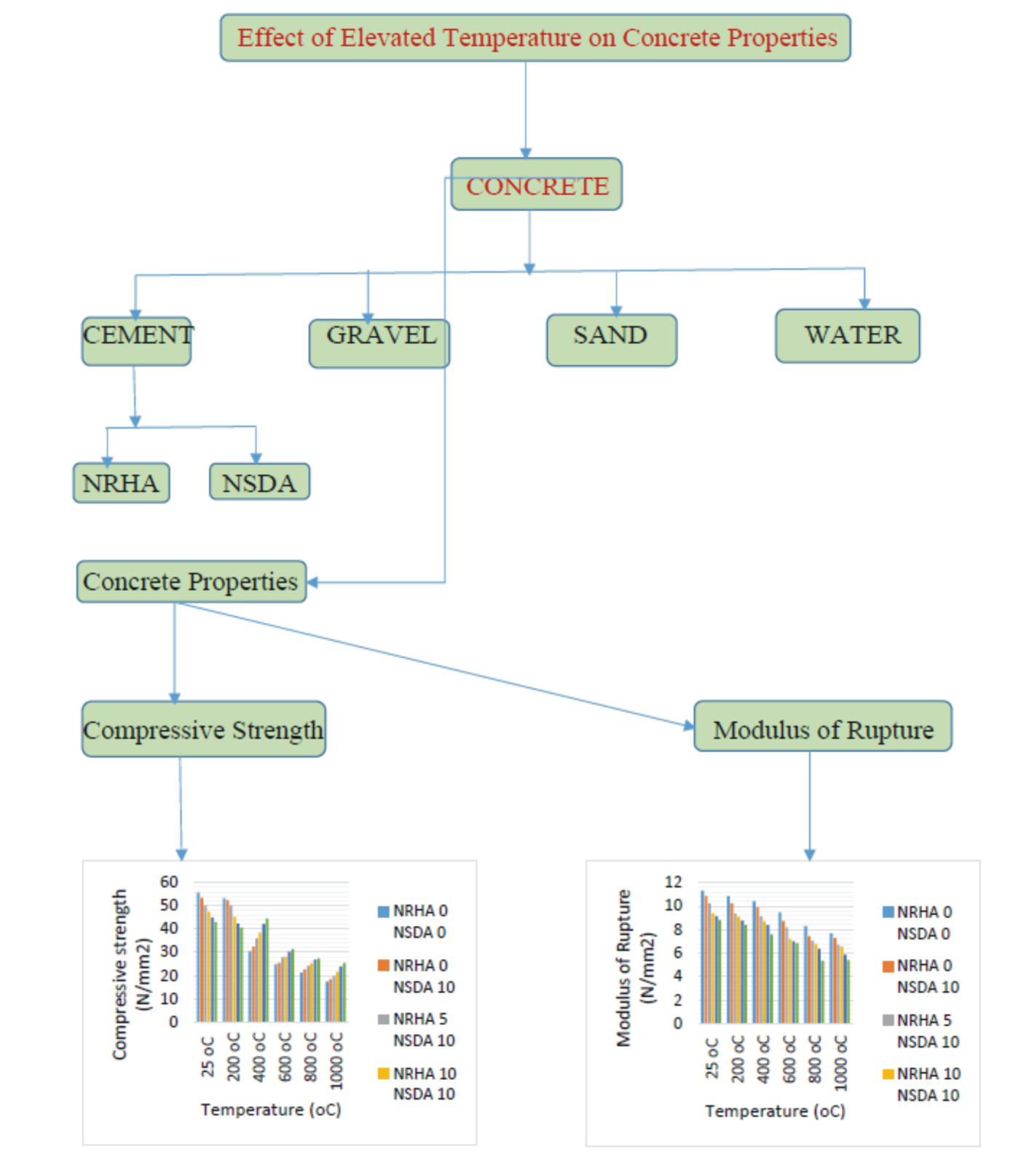

Effect of Elevated Temperatures on Mechanical Properties of Concrete Blended with Nanosized Sawdust Ash and Rice Husk Ash

Keywords:

Concrete, nanosization, compressive strength, modulus of rupture, high temperatures, nanosized sawdust ash (NSDA), nanosized rice husk ash (NRHA)Abstract

The need for sustainable greener concrete structures has necessitated the adoption of pozzolanic materials to serve as alternatives to conventional cement whose production contributes to carbon dioxide emissions which advances global warming, apart from its cost implications and environmental pollution. The desire for concrete with improved performance has prompted more studies and attention to development of nano-concrete. However, there is minimal information available on the structural behaviour of concrete that is based on nanosized replacement materials. At elevated temperature, concrete experiences severe deterioration with significant physio-chemical transformations which leads to the breakdown of the cement gel structure, strength loss and structural-cracking. In fire resistance design, compressive strength and modulus of rupture of concrete at high temperatures, is of basic interest. This study analyzed the effect of high temperatures of 25 °C, 200 °C, 400 °C, 600 °C, 800 °C and 1000 °C on blended concretes made with nanosized sawdust ash (NSDA) and nanosized rice husk ash (NRHA). Blended concretes of mixes containing 10% of NSDA with 5%, 10%, 15% and 20% NRHA were produced. Six varied mixes were produced for the concrete cubes and beams. Workability test was carried out on each of the six mixes. Concrete cubes of sizes 150mm x 150mm x 150mm and concrete beams of sizes 150mm x150mm x 500mm were produced to determine the compressive strengths and modulus of rupture respectively. The concretes were cured for 21, 28, 60 and 90 days by total immersion in water. Generally, it was observed that there was reduction in strength with increase in temperature and NRHA content from the ambient temperature (25 oC) up to 200 oC. The concretes’ compressive strength reduced with increase in temperature but increased with increase in NRHA replacement, at temperatures of 400 oC and beyond. At all temperatures, the modulus of rupture (MOR) values reduced as the percentages of NRHA increased. After 28 curing days at NRHA 5% NSDA 10% replacement when compared to the strength of control specimen, strength exhibited decrease of 10.02%, 5.81% with an increase of 18.67%, 12.40%, 13.85% and 15.36% at temperatures of 25 oC, 200 oC, 400 oC, 600 oC, 800 oC and 1000 oC respectively, while the modulus of rupture, (NRHA 5% NSDA 10%) at ambient temperature showed a decrease of 8.60%, 10.85%, 19.84%, 31.18% and 34.21% at temperatures of 200 0C, 400 0C, 600 0C, 800 0C, and 10000C respectively. The results revealed the beauty of nanosization, hence it is suitable for adoption as it improves the mechanical properties of concrete.