Synthesis and utilization of rice husk cellulose nanocrystals as biocomposite film reinforcement for edible packaging application

Keywords:

Rice husk, cellulose nanocrystal, Nanocomposite, PackagingAbstract

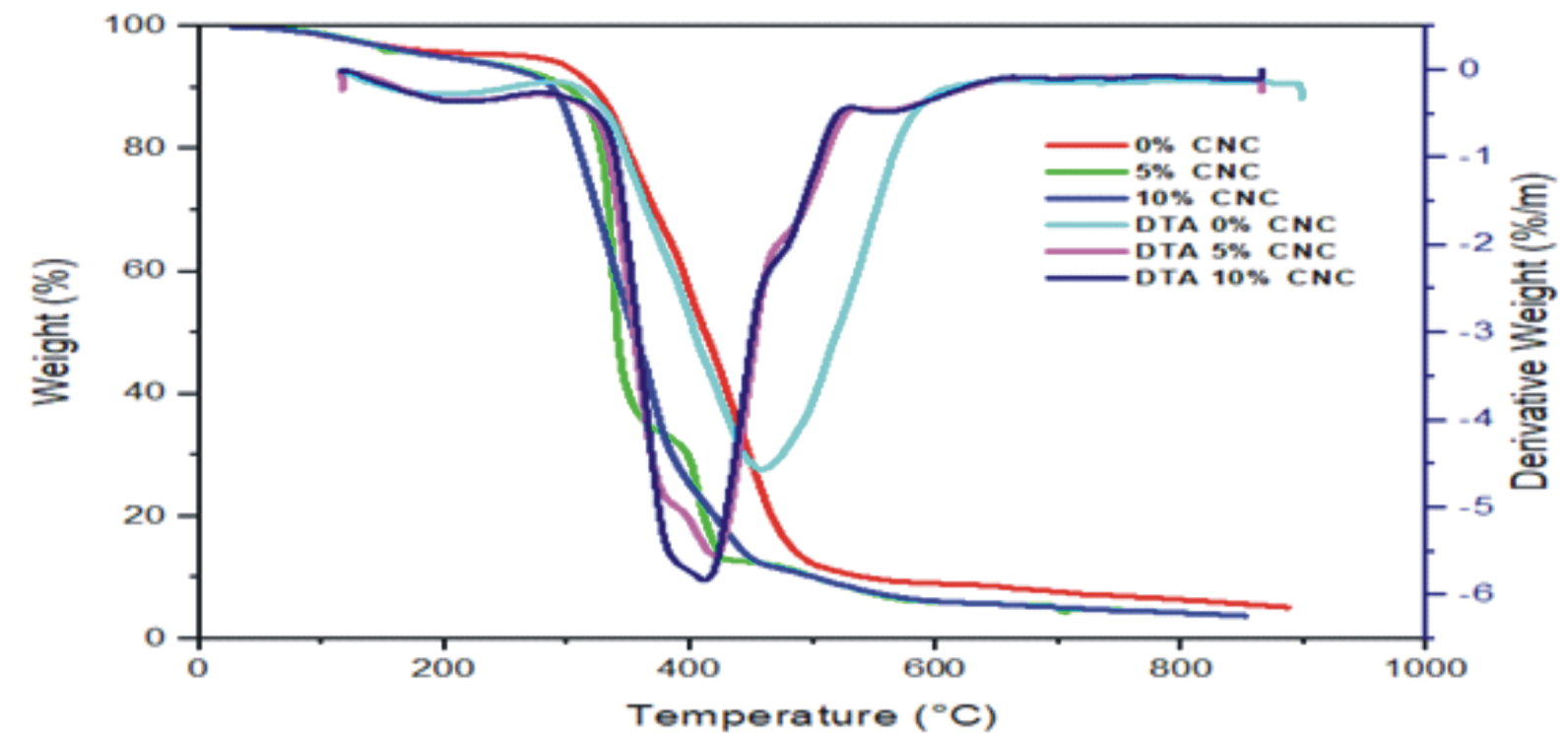

The high-value application of rice husk, a renewable, easily accessible, and plentiful agricultural waste, demands further study. The goal of this research is to create rice husk cellulose nanocrystals (CNC) reinforced carboxyl methylcellulose (CMC)-gelatin film using solution casting method for use in edible packaging. CMC-gelatin nanocomposites reinforced with CNC through solution casting technique were successfully fabricated. Investigations were conducted into how CNC content affected the morphological, mechanical, water vapor permeability (WVP), degradability, and thermal characteristics of carboxyl methylcellulose-gelatin-CNC films. The results of the scanning electron microscopy showed a needle-like form with dimensions of 81 to 286 nm in length, 8 to 21 nm in diameter, aspect ratio of 17, and crystallinity index of 0.82. The WVP of the films decreased from 3.10 x 10-6 g/m.h.Pa to 2.32 x 10-6 g/m.h.Pa. The tensile strength of the nanocomposite films increased from 6.83 MPa to 7.80 MPa, elongation at break reduced from 81.50% to 63.75% while thickness increased from 0.13 um to 0.25 um by CNC incorporation. The degradability of the nanocomposite films also reduced from 0.24 wt% to 0.21 wt%, while the thermal stability of the nanocomposite films increased from 283oC to 363oC. The result indicates clearly the vantages in the use of CNC reinforced CMC-gelatin to replace the extensive use of petroleum based material.