Effects of Percentage Composition of Essential Chemicals in Portland Limestone Cement on the Strength and Workability of Concrete

Abstract

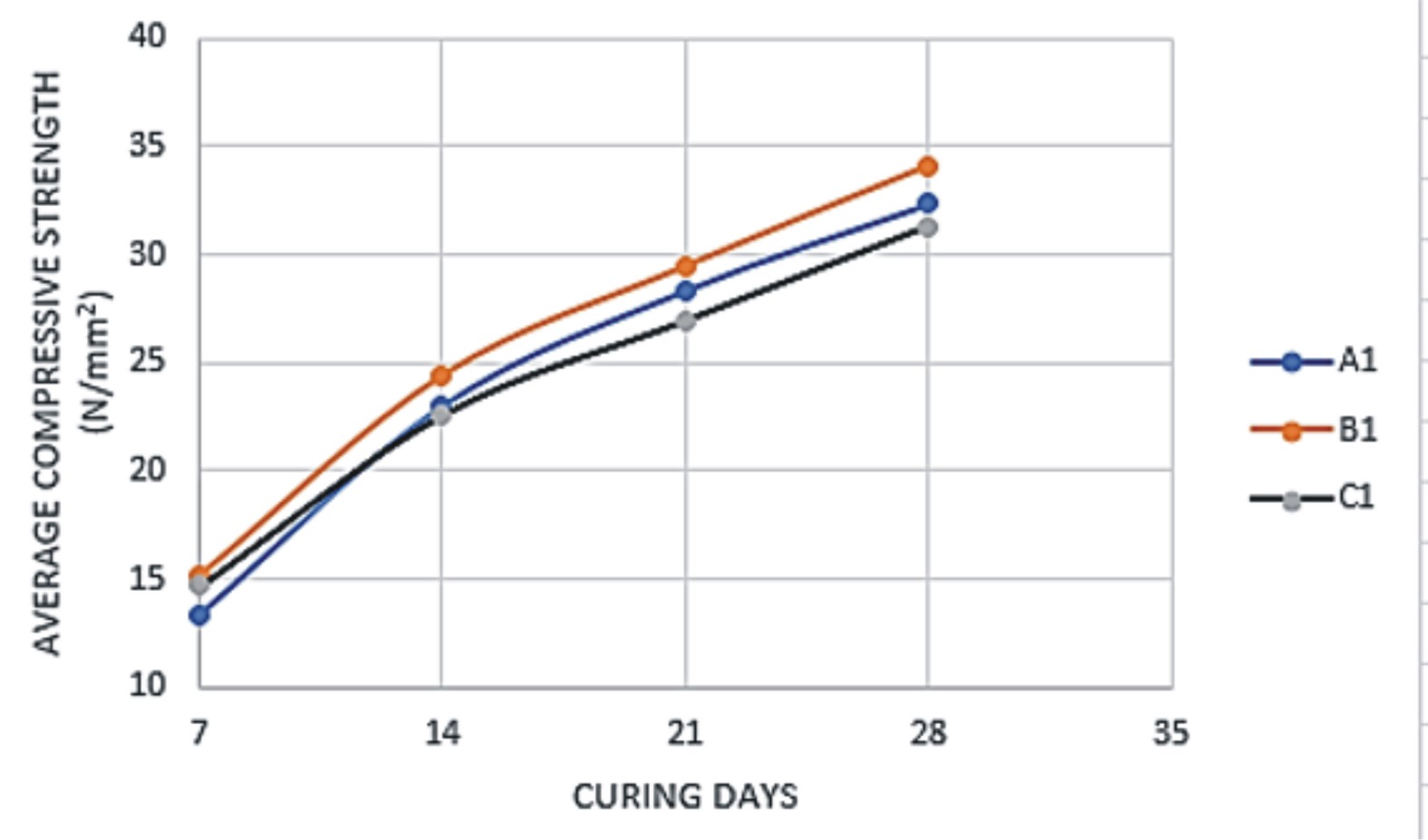

This paper investigates the effects of percentage composition of essential chemicals in Portland limestone cements on the strength and workability of concrete. Three samples of Portland limestone cements, produced by different manufacturers that sourced their raw materials from different locations were used in this study. The samples were labeled Sample A, Sample B and Samples C. They were classified as CEM II, grade 42.5N in conformity with BS EN 197-1 (2011) and ASTM C150 (2019). Properties of concrete materials like chemical composition, sieve analysis, specific gravity and fineness tests were investigated. An X-ray fluorescence test was conducted on the three samples of Portland limestone cements. Workability and compressive strength tests were also carried out on concrete samples. The results revealed a variation in the chemical composition of the three samples. For the key chemical components, SiO2, (A=8.694, B=12.418, C=9.516), for Al2O3, (A=5.042, B=5.945, C=9.516), for Fe2O3, (A=3.676, B=3.735, C=2.836), for CaO, (A=77.171, B=70.326, C=74.178) and SO3, (A=3.385, B=2.396, C=3.124). This variation in the chemical composition was found to be from different limestone sources, other raw materials and manufacturing process. These variations impacted the performance of the concrete as samples with higher SiO3, Al2O3, and Fe2O3 gave higher strength. Moderate CaO and low MgO exhibited high slump values and compressive strength. However, all the samples gave desirable consistency and strength. The average of three cubes cured for 7, 14, 21 and 28days was tested for compressive strength. Sample B, due to its higher Silica Oxide, Alumina Oxide, and Iron oxide content gave higher values of 15.17N/mm2, 24.40N/mm2, 29.43N/mm2 and 34.07N/mm2 for strength at 7, 14, 21 and 28days. Sample A gave 13.40N/mm2, 23.03N/mm2, 28.33N/mm2 and 32.33N/mm2 for 7, 14, 21 and 28days. Sample C gave 14.67N/mm2, 22.57N/mm2, 26.93N/mm2 and 31.3N/mm2 for 7, 14, 21 and 28days.