Response of mild steel corrosion rate in h2so4 solution to the input concentration of hypoxanthine as inhitor and its inhibition efficiency

Keywords:

Mild steel, corrosion rate, sulphuric acid, hypoxanthine, inhibition efficiencyAbstract

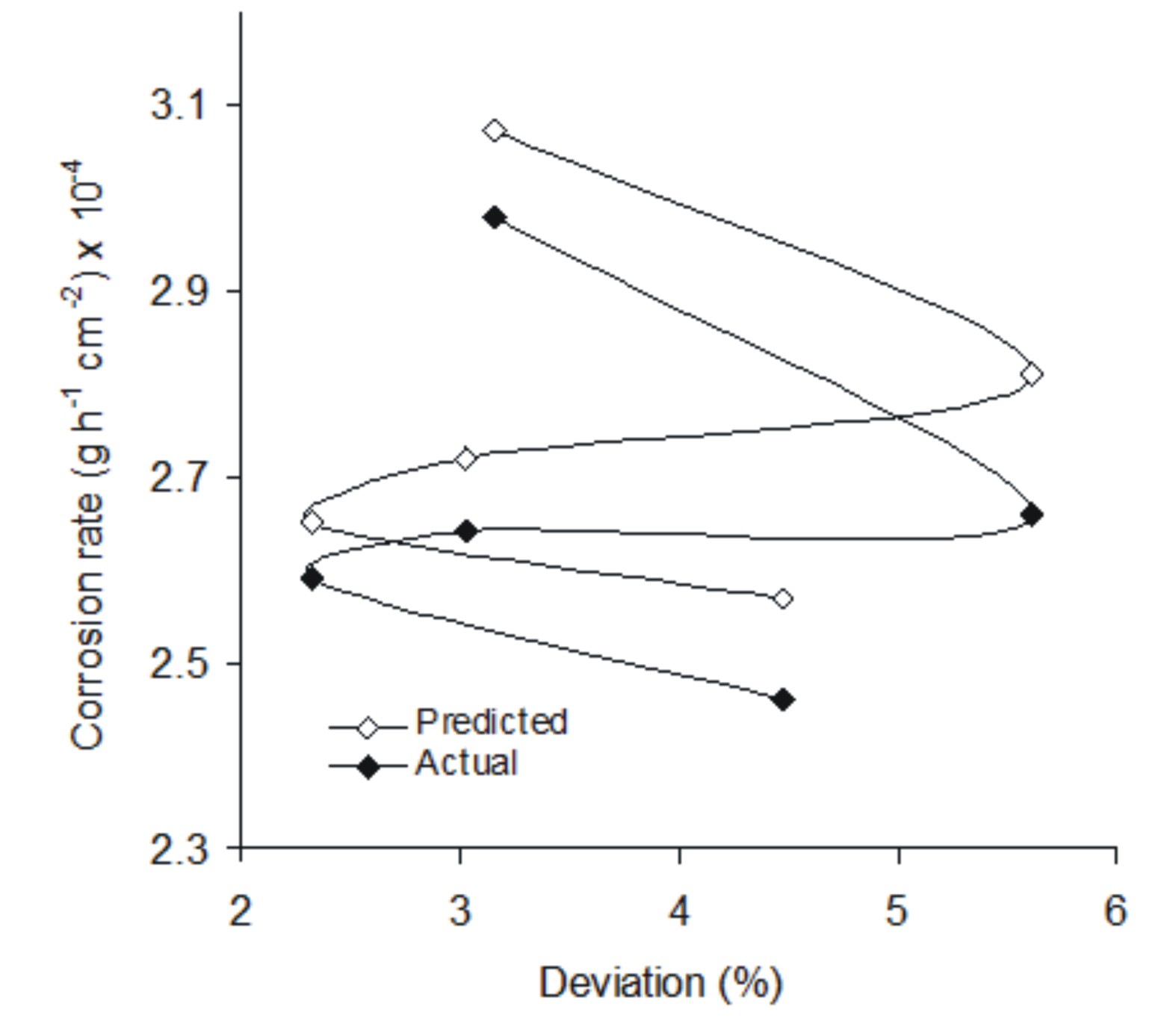

This paper evaluates the response of mild steel corrosion rate to the inhibitor (hypoxanthine) concentration and inhibition efficiency using a derived empirical model; ξ = Ҽγ-K + Ϧη-N. In the course of the derivation, the range of values for the process parameters used were 2.46 x 10-4 - 2.98 x 10-4 (g h-1cm-2), 0.002-0.01(mol dm-3) and 53.98- 61.94 (%) for corrosion rate, inhibitor concentrations and inhibition efficiencies respectively. The validity of the model is strongly rooted on the core model structure; ξ – Ϧη-N ≈ Ҽγ-K. The model-predicted results agree with previous research on the inverse relationship between the corrosion rate and inhibitor concentration & inhibition efficiency. The standard error incurred in predicting the model based corrosion rates relative to the actual results was < 0.04%, implying over 99% model confidence level. Corrosion rate per unit inhibitor concentration and inhibition efficiency were evaluated as - 0.0065 & - 0.00625 g h-1 cm-2 /mol dm-3 and - 6.53 x 10-6 & - 6.28 x 10-6 g h-1 cm-2 / %, using the actual and model-predicted results respectively. Furthermore, the correlations between these highlighted parameters, as evaluated from both results were all > 0.96. The overall maximum deviation of model-predicted corrosion rate from actual results was 5.62%.