Stochastic process assessment for XP600 printhead failures: A Weibull method study

Keywords:

Printhead, Reliability, Weibull, Failure, MaintenanceAbstract

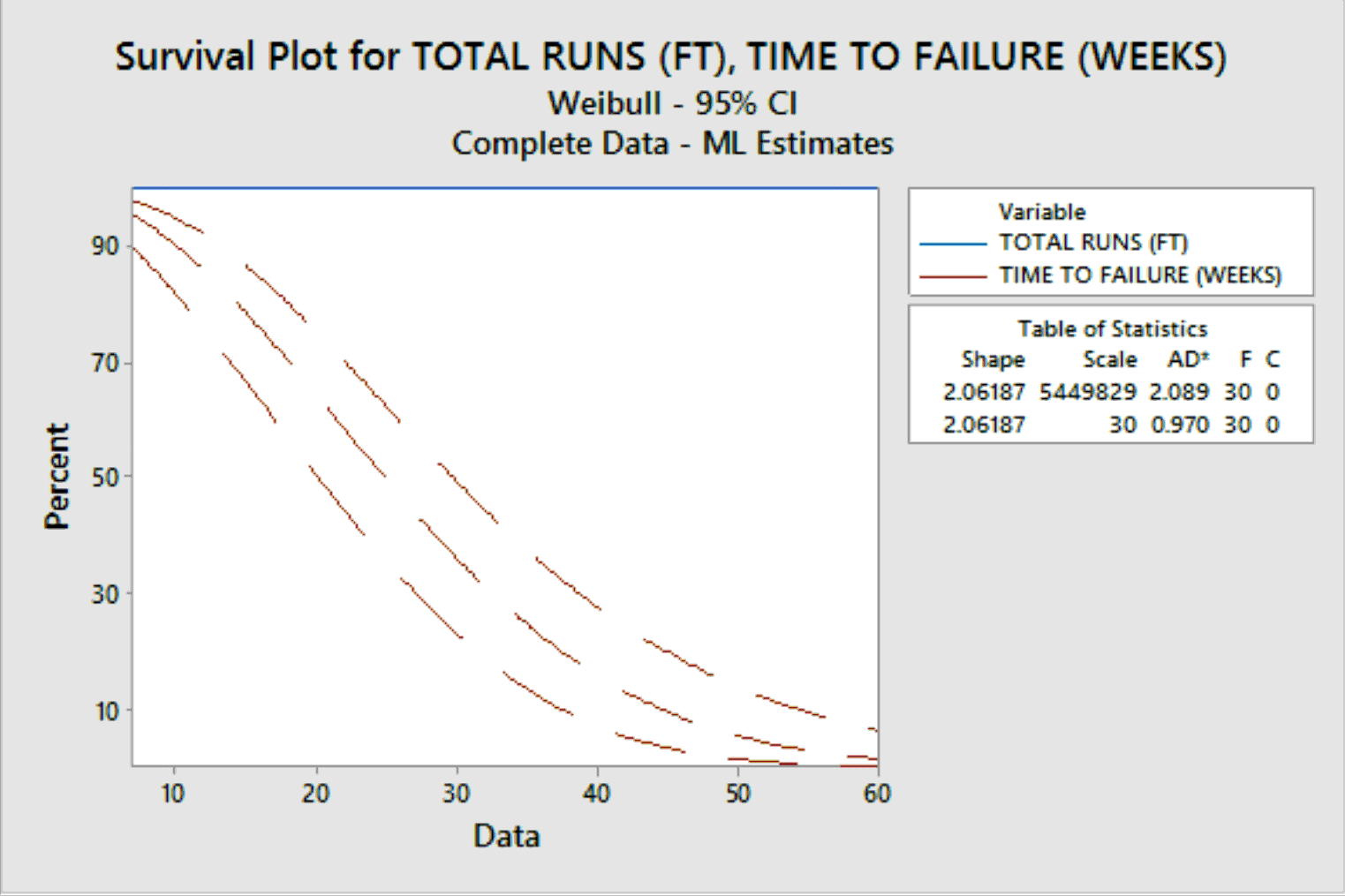

This research presents a thorough reliability assessment of XP600 printheads using the Weibull method, examining the variables "Time to Failure" and "Total Runs" to understand their distributional characteristics and implications for maintenance. Both variables share a shape parameter (β) of 2.06187, indicating a right-skewed distribution. Notably, "Time to Failure" exhibits lower variability with a scale of 29.7615 weeks, while "Total Runs" reveals broader variability with a scale of 5449829 feet. Anderson-Darling goodness-of-fit tests underscore the superior reliability of "Time to Failure" (adjusted value: 0.970). Practical applications advocate for a time-based maintenance strategy, with the categorization of printheads based on both time and total runs for risk-based interventions. The integrated approach proposed extends beyond XP600 printheads, offering a nuanced decision-making framework for industrial printing technologies. Future research should explore intricate relationships between time and total runs, translating findings into actionable strategies for enhanced performance and longevity. This research serves not only as a reliability exploration but also as a catalyst for efficient maintenance practices in industrial printing technologies.