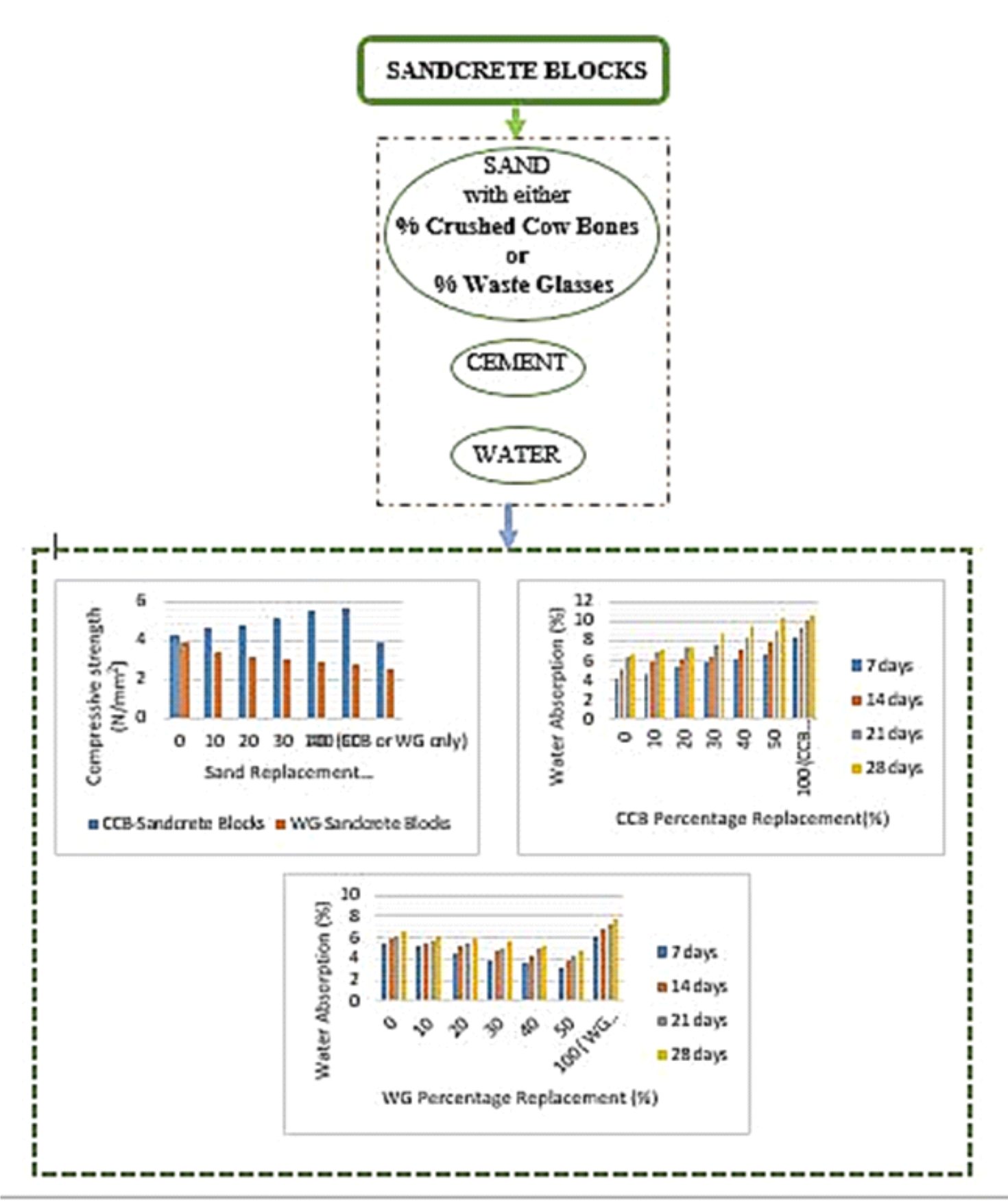

Experimental Investigation on Replacement of Fine Aggregate with Crushed Cow Bones and Waste Glasses in Production of Sandcrete Blocks

Keywords:

Sandcrete blocks, Crushed cow bone (CCB), Waste glasses (WG), Compressive strength, Water absorptionAbstract

The increasing demand for infrastructural development in developing nations has intensified the global adoption of sand as fine aggregate in construction works. To overcome the restrictions placed on the extraction of natural sand by most communities, satisfying its stretched need with gross reduction in construction cost in order to achieve sustainable development, there arises the need for consideration of the use of cheaper and locally available materials. In this study, crushed cow bones (CCB) and waste glass (WG) were employed as sand replacement materials for investigation of compressive strength and water absorption of sandcrete blocks, at 0%, 10%, 20%, 30%, 40%, 50% and 100% sand replacements using cement/combined aggregate ratio of 1: 6. Seven hollow blocks of dimension 450 mm x 225 mm x 225 mm were produced for each percentage sand replacement. A total of 168 hollow blocks were produced, 84 blocks for sand-CCB-blocks and 84 blocks for sand-WG-blocks. The blocks were moulded manually and were tested after curing by water sprinkling for 7, 14, 21 and 28 days. The blocks were cured by sprinkling them with water twice daily. As for 50% sand replacement with CCB blocks and WG blocks, the compressive strength was 4.71 N/mm2 and 2.29N/mm2 at 7days curing respectively, and 5.67 N/mm2 and 2.82 N/mm2 at 28-days curing respectively, both were within the range of minimum strength stipulated in NIS 87. The 2.82 N/mm2 compressive strength value for 50% replacement levels still qualified the WG-Sandcrete blocks used for this investigation to be classified as non-load bearing solid block. 10.27% and 4.80% were obtained as the water absorption capacity of CCB and WG sandcrete blocks respectively, at 50% sand replacement after 28 curing days. All water absorption values obtained from both CCB and WG sandcrete blocks fell below the maximum NIS stipulation of 12%. Based on the study outcome, CCB and WG can be used reliably as a partial replacement of sand; hence they are recommended for adoption in construction activities as it reduces environmental pollution, production cost of sandcrete blocks and promotes sustainable structural development.