Comprehensive Analysis of Thatch Grass from Southeastern Nigeria for Sustainable Particleboard Production

Keywords:

Thatch Grass, Biomass, hyparrhenia, Particleboard, Sustainable developmentAbstract

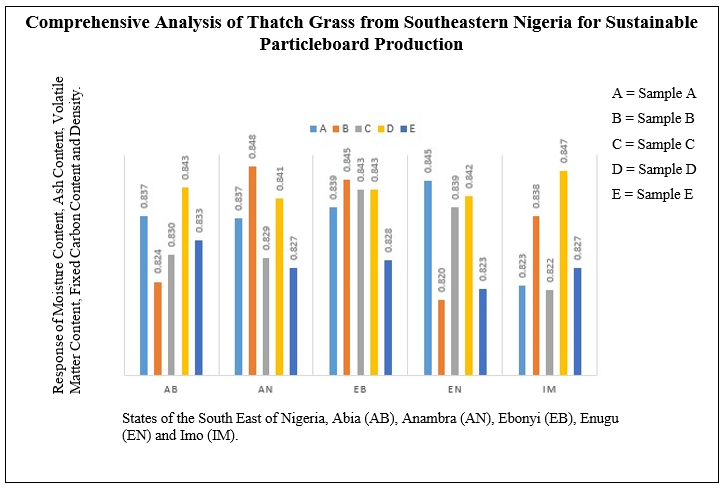

This study presents an investigation into the viability of thatch grass as a sustainable raw material for particleboard production. The transition from traditional thatch to modern roofing materials has resulted in environmental challenges, including increased wildfire risks. The key objectives of the study was to investigate the suitability of hyparrhenia grass for sustainable particleboard production. Proximate analysis, following ASTM standards, was employed to assess moisture, ash, volatile matter, and fixed carbon content. Density was determined using a Pycnometer. The study encompassed samples from five Southeastern Nigerian states, employing triplicate analyses for each parameter. The study contributes to regional industrial development and aligns with sustainable development goals; while emphasizing ecological and economic benefits. The methodology involves proximate analysis and density assessment, employing standardized protocols for moisture, ash, volatile matter, and fixed carbon content determination. Moisture content falls within ASTM E871-82(2019) standards, validating suitability for particleboard production. Ash content ranges from 2.238% to 2.837%, indicating potential compatibility with particleboard production standards. Volatile matter content (75.565% to 77.761%) aligns with biomass material standards, supporting suitability. Fixed carbon content falls within the range of 16.338% to 18.305%, meeting ASTM D3172-13 (2021)e1 standards. Bulk density ranges from 0.820 g/ml to 0.848 g/ml, complying with ASTM E873-82 (2019) standards for biomass materials. Results indicate that hyparrhenia meets ASTM standards for particleboard raw materials, showcasing promising characteristics. The findings advocate for the ecological and economic benefits of hyparrhenia-based particleboard, addressing environmental threats and contributing to regional industrial development. Collectively, these findings underscore the potential of thatch grass as a promising and sustainable resource for particleboard production. The alignment with established standards in key properties, coupled with its regional abundance, positions thatch grass as a viable and environmentally friendly alternative for particleboard production. Further exploration and development in this direction could contribute to the expansion of biomass resources in the particleboard industry, fostering economic and ecological sustainability.