Effect of projectile shape on laminate composite materials (mild steel-bulk metallic glass-dyneema) as ballistic protection using computational analysis

Keywords:

Blunt; Bulk Metallic Glass; Conical; Deformation; Dyneema; Mild Steel; Von Mises stresses.Abstract

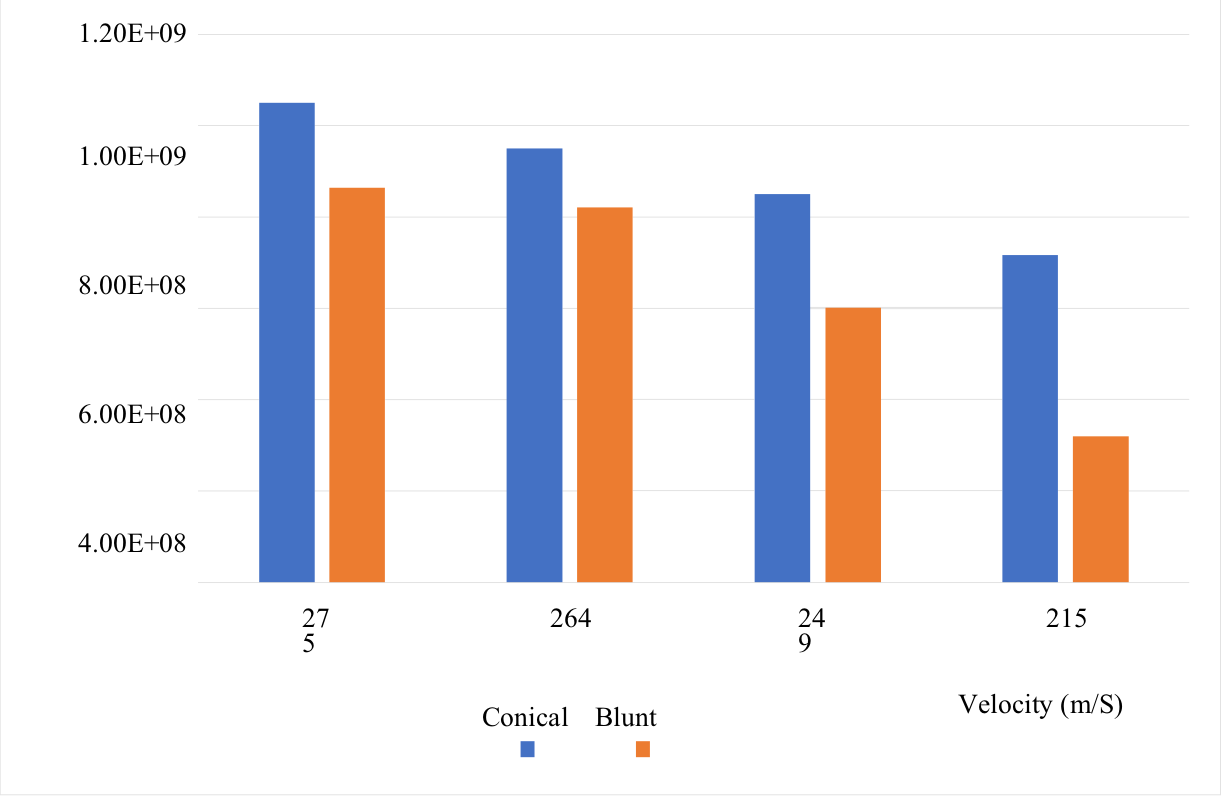

This study investigated the influence of projectile geometry on the ballistic performance of laminate composite materials for protective systems. Advanced computational analysis using Abaqus Explicit FEA software compared two projectile configurations, blunt-nose and conical, against laminate materials including mild steel, Bulk metallic glass, and Dyneema, with a 9 mm plate thickness target. The study reveals that over a velocity range of 215 m/s to 275 m/s, the conical projectile induces significantly higher Von Mises stress levels compared to the blunt-nose projectile. This effect is attributed to the conical projectile's piercing action causing localized plastic strain and petal-like formations, while the blunt projectile results in plug ejection from the target material. The research highlights the complex failure mechanisms associated with different projectile geometries, with the conical projectile inducing radial necking and petalling, and the blunt projectile causing indentations and plug ejection. These findings underscore the reproducibility of established trends and contribute to understanding the ballistic behavior of laminate composite materials.