Influence of heat treatment parameters on mechanical properties and microstructure of Cu-10wt%Si-2wt%Ni alloy

Keywords:

Brine, Copper-Silicon, Nickel, Solid solution heat treatment, Tensile PropertiesAbstract

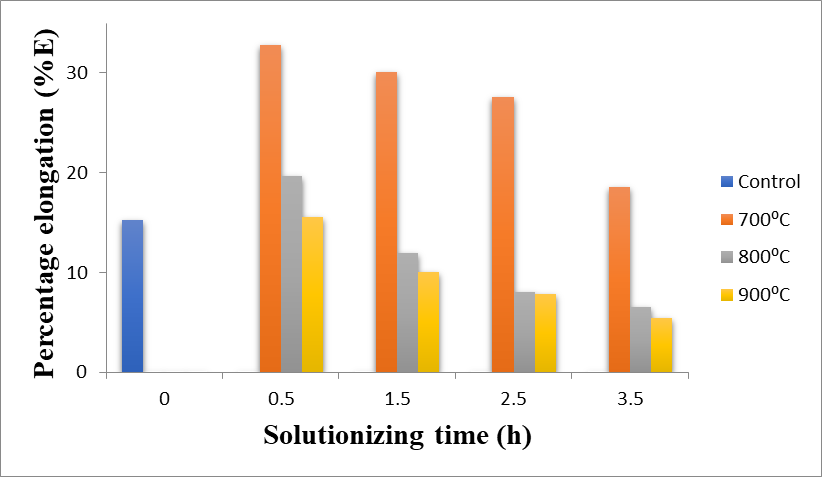

The impact of heat treatment parameters on the tensile properties and microstructural characteristics of Cu-10wt%Si-2wt%Ni alloy produced by sand casting technique were investigated. The samples were subjected to solid solution heat treatment, brine quenched and subsequently analyzed for ultimate tensile strength, elastic modulus, yield strength, and microstructural characteristics. The results showed that solid solution heat treatment refined and modified the structure of Cu-10wt%Si-2wt%Ni alloy and significantly improve the tensile properties. Maximum yield strength (160.8 MPa) and ultimate tensile strength (193.83 MPa) were observed at 800°C for 2.5 hours after heat treatment while maximum elastic modulus of 1979.17 MPa were observed at 900°C for 3.5 hours. Maximum percentage elongation value of 32.79% was observed after solid solution treatment at 700°C for 0.5 hours. Microstructural analysis results revealed a transition from coarse grains dispersed within the copper matrix in the control sample to finer grains of intermetallic compounds in the heat-treated specimens.