Particle Size Variation on the Characteristics of Pretreated APWF-LLDPE Composite for Furniture Component of Automobile Parts Production

Keywords:

APWF, LLDPE, APWF-LLDPE composite, particle size, pre-treatment, mechanical characteristicsAbstract

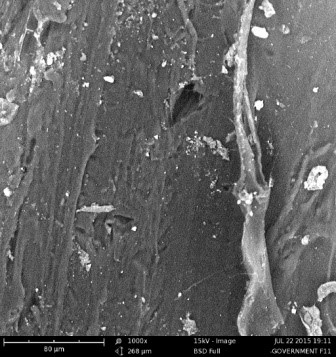

The study examined the variation of particles on the characteristics of avocado pear wood fiber-linear-low-density polyethylene (APWF-LLDPE) composite by several treatment rout. The avacodo wood (APWF) with sizes of 150, 180, 250, 425 and 850 µm was compounded in the linear –low-density polyethylene (LLDPE) matrix. The APWF with content ranges from 5-25 wt.% for the variant particle sizes were treated with NaOH (NST), NaOH/CH3COOH (AAT), NaOH/ CH3COOH/MAPE (MPT); and blended with LLDPE to form APWF-LLDPE composite, respectively. The manufactured composites made by blending of APWF and LLDPE were passed through mechanical, water absorptive, FTIR and SEM testing, The observable outcome indicated that the characteristics and the resistance to sorption capacity of APWF-LLDPE composite enhanced at 150 µm particle of APWF. The greatest properties of APWF-LLDPE composite was obtained after compounding the APWF modified with NaOH/CH3COOH/MAPE at the minimum size range and LLDPE matrix. The ultimate strength, modulus of elasticity, bending strength, bending modulus, Brinell hardness, impact energy per unit area and sorption resistance at this particle and 25 wt.% content were equivalent to 24.85 MPa, 0.871 GPa, 63.11 MPa, 0.821 GPa, 788 Pa, 90.35 KJ/m2 and 3.49 %, respectively. The APWF-LLDPE composite chemically modified NaOH/CH3COOH/MAPE is a suitable alternative for furniture panel of automotive parts.