The Potentials of using Neem Bark Flour in Polymer Composite Production for Refrigerator Components

Keywords:

Neem bark flour; neem bark flour-high density polyethylene composite, mechanical properties, production; potentialsAbstract

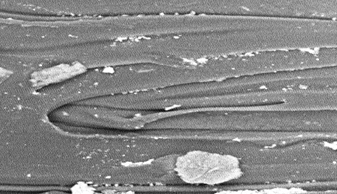

The particle variation and content of neem bark flour (NBF) on the mechanical properties of neem bark flour-high density polyethylene (NBF-HDPE) composite were examined. The HDPE and NBF were thoroughly mixed at 10-40 wt.% and particles of 10(2000 µm), 20 (850 µm), 40 mesh (425 µm); compounded with aid of an injection moulding machine, respectively. The NBF-HDPE composite sample produced was passed through micro-mechanical testing to ascertain the ultimate tensile strength (UTST), elongation (EL), elastic modulus (EMO), impact strength (IST) and Brinell hardness. (BHA), respectively. Scanning electron microscopic (SEM) and Fourier transform infrared (FTIR) was performed for HDPE, NB, and NBF-HDPE composite, respectively. The outcome from this research indicated that the NBF-HDPE composite UTST and EL lowered than the fresh HDPE with 10 mesh particles (2000 µm) of the NBF in HDPE matrix yield better values of 18.91 MPa and 7.5 %, respectively. However, EMO, IST and BHA of NBF-HDPE composite were greater than new HDPE maintaining an optimum value of 0.53 GPa, 95.77 KJ/m2 and 452.2 BHN at 40 mesh, 10 mesh and 20 mesh particles of NBF in the matrix of HDPE, respectively. The valued emanated confirmed that NBF-HDPE composite can be alternatively utilized for refrigerator parts.