Evaluative Analysis of Specific Wear Rate of Glass Fibre Reinforced Epoxy Resin (GFRP) based on Applied Load and Weight Loss while Sliding Under Dry Medium

Keywords:

Specific wear rate, glass fibre-epoxy resin composite, applied load, weight loss, dry mediumAbstract

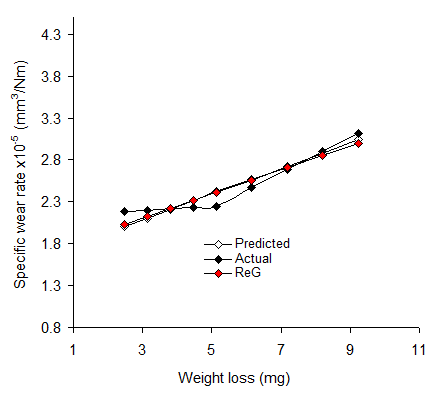

The specific wear rate of glass fibre reinforced epoxy resin while sliding under dry medium was evaluated based on the weight loss (of the composite while sliding) and applied load. The predictive analysis was carried out using a derived empirical model; Ⱳ = N(eϦω + eẞƐ ) - К, whose validity was rooted on the core model structure; Ⱳ + К ≈ N(eϦω + eẞƐ ), considering that both sides of the structure are correspondingly almost equal. The symbols Ⱳ, ω and Ɛ are specific wear rate of the glass fibre-epoxy resin composite (mm2/Nm), weight loss of the composite while sliding (mg) and applied load on the composite to enable sliding (N), while К, N, Ϧ and ẞ are equalizing constants respectively. Results generated from experiment, derived model and regression model are characterized by very similar trend, spread of results and corresponding point values. Evaluated correlations from derived model and experimental results, between the specific wear rate and applied load & weight loss are 0.9988 & 0.9270 and 0.9980 and 0.9625 respectively. The overall standard error, associating prediction of specific wear rate of the composite, is 0.11%, for every change in the applied load and composite weight loss. This gives a model confidence level above 99%. The specific wear rate of the composite, per unit applied load and weight loss are 0.0116, 0.0130 & 0.0120 mm3 /N2m and 0.1377, 0.1543 & 0.1425 (mm3 /Nm)/mg respectively. Overall maximum deviation of the model-predicted specific wear rate from experimental results was 8.04%. The derived model will predict the specific wear rate of the composite, within the experimental results range, on substituting into the model, values of the applied load on the composite and its corresponding weight loss, providing the boundary conditions are considered.