Wear resistance and tensile behaviours of bamboo fibre and mangifera indica particulate epoxy resin composite

Keywords:

Epoxy resin, Bamboo fibre, Mangifera indica particulates, tensile strength wear rateAbstract

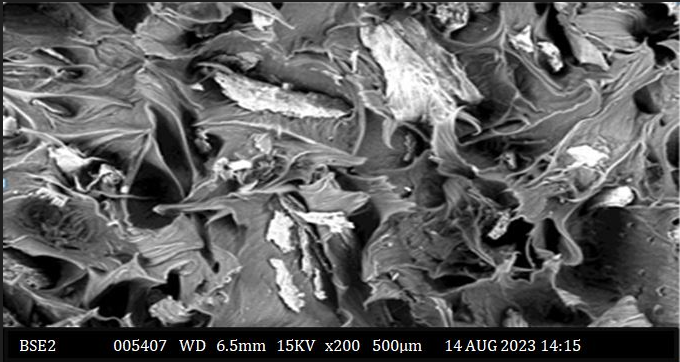

Pursuing an eco-friendly environment has resulted in the recent creation of polymer matrix/green plant fibre composites. The study explored the effect of bamboo fibre and mangifera indica particulates on epoxy resin bio-composites structure and mechanical properties. The materials used are bamboo fibre, mangifera indica particulates, and epoxy resin sourced locally. After the thin layers of bamboo bark were carefully removed, the bamboo fibre was extracted manually by peeling down the cylinder culm of the bamboo to produce strips with varying diameters and lengths. Also, the mesocarps from Mangifera indica fruit were removed manually and the endocarps obtained were subjected to sun drying. The endocarps were then manually cracked and separated to obtain the required shells. The biocomposite samples were fabricated through the hand layup technique. The composite samples were fabricated in three separate groups of bamboo fibres of 5wt%, 10wt%, and 15wt% with variable percentages of Mangifera indica particulates of 5wt%, 10wt%, 15wt%, 20wt%, and 25wt% using epoxy resin. The tests carried out are tensile strength by ASTM 638-10 standard test and wear resistance test. A scanning electron microscope was conducted to analyze the results of tensile strength test. The results show that the tensile strength of composite samples reinforced with 10wt% bamboo fibre and varied percentages of Mangifera indica particulates were superior compared to those reinforced with 5wt% and 15wt% bamboo fibre and varying percentages of Mangifera indica particulates. The structural analysis revealed that significant improvements in tensile strength can be attributed to fibre-matrix interfacial bonding and fibre alignment along the direction of load application. The decrease in wear rate can be attributed to an increase in the reinforcing content, which hardened the hardness of the composites. It was also established that increasing the period of wear resistance testing causes an increase in wear rate across all weight fractions