Effect of Eziadda Clay on Foundry Properties of Azumili Blue River Sand Beach

Keywords:

Azumili Blue River Sand Beach, Foundry properties, core making, chemical analysisAbstract

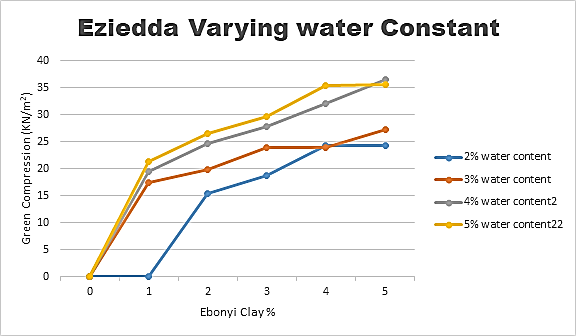

The study focused on the effect of Eziadda clay on Azumili Blue River Sand Beach in Aba, Abia state, Nigeria. The chemical analysis was carried out on three sand beaches using X-ray fluorescence (XRF). Azumili Blue River Sand Beach, Aba, Abia State is made up of silica SiO2 (93.616%), K2O (0.15%), CaO (0.40%), Fe2O3 (1.68%), Al2O3 (3.15%), and 0.084% clay, according to the results of the chemical analysis. While the sand at Ogbo Hill River is composed of silica (89.99%), K2O (0.1563), CaO (0.075%), Fe2O3 (0.17769%), Al2O3 (Al2O3 5.410%), and Eziedda clay contains Fe2O3 (0.3686%), SiO2 (39.541 %), and Al2O3 (29.69 %), Akwuke Sand Beach in Enugu State contains silica SiO2 (91.72%), K2O (0.17%), CaO (0.48%), Fe2O3 (0.84%), and Al2O3 (3.191). Because Azumili Blue River Sand Beach has a high silica concentration and 0.084% clay content, it was chosen for mechanical analysis. The following data were obtained for green strength (35.00kN/m2), dry strength (258.0kN/m2), compatibility (28.60%), permeability (5.23), and moisture content (3.25%) from the mechanical characteristics test using a 5% core sand mixture and Eziedda clay. According to the findings, a core of 3-5% Eziedda clay and 3-5% water is appropriate for casting light grey iron, malleable iron, and nonferrous alloys.