Bi-Model-Based Multi-Criteria Optimization Decision Support System for Strategic Maintenance Scheduling in Food Manufacturing Industries

Keywords:

Maintenance Optimization; Maintenance Strategy; Decision Support System; Maintenance Cost; ReliabilityAbstract

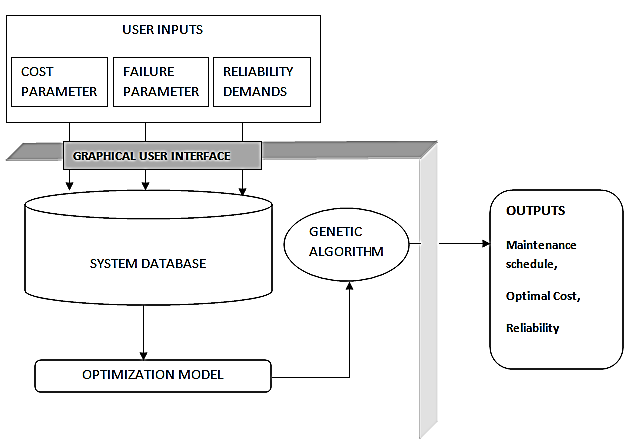

The importance of maintenance is ever increasing as a result of the widespread automation of manufacturing systems and the capital expenditure allocated to it, thus making maintenance of manufacturing equipment an investment opportunity to be maximized and not a cost center. The economic downturn continuously drives manufacturing organizations to seek for more efficient strategies to manage assets maintenance. Thus, in this study a decision support system was developed and presented in this study, of which the aim is to develop a schedule for future maintenance actions for each manufacturing component that is repairable over the period time. This is obtained through the optimization of a bi-model-based multi-criteria optimization model. The developed system was validated using an industrial case study and it proved to be highly effective and less cumbersome in obtaining the optimal maintenance strategy from any manufacturing setting.