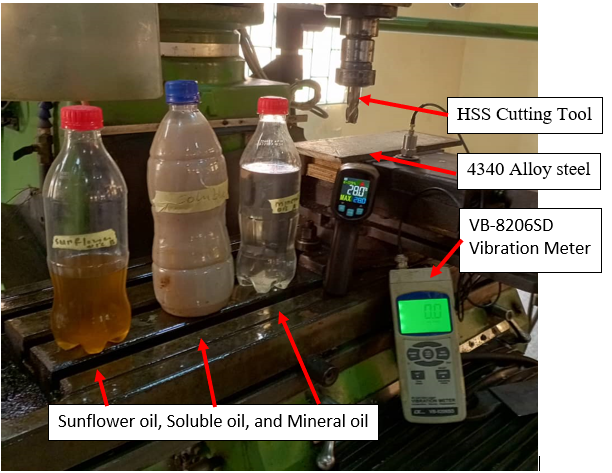

Chatter in CNC milling machine of 4340 alloy steel under varying lubricating conditions

Keywords:

Chatter Vibration, End Milling, Cutting Fluid, Vegetable Oil, Sunflower OilAbstract

In this study of chatter in a CNC milling machine of 4340 alloy steel under varying lubricating conditions, the study conducted an experimental study of machining vibration on 4340 Alloy Steel with various cutting fluids. The fluids employed were soluble oil, mineral oil and sunflower oil. The Physiochemical Properties of soluble oil, Sun-Flower Seed Oil and Mineral Oil were determined. The study employed Box-Behnken Design for the machining vibration study, with three factors and three levels of parameters, including cutting speed, feed rate, and depth of cut. The vibration meter VB-8206SD machine was used to measure the machining vibration during the experimentation under the three-lubrication process. The interaction study shows that the cutting speed, when increased with the increase of feed rate and the depth of cut, reduces the vibration. Also, the increase in depth of cut from 0.5 mm to 1.5 mm leads to an increase in the machining vibration; the highest vibration of 62 (mm/sec) was observed. The optimal machining vibration parameters for this study are a cutting speed of 2000 rpm, feed rate of 134 mm/rev, and depth of cut 0.5 having machining vibration of 40.18 mm/sec, 33.72 mm/sec, and 28.72 mm/sec, respectively. The results show that mineral oil reduces chartered vibration by 13% compared to soluble oil-cutting environments. Furthermore, sunflower reduces the vibration by 8% compared to mineral oil and 20% with soluble oil. Therefore, the study concluded that manufacturers can employ sunflower oil as a viable cutting fluid for a sustainable machining process.