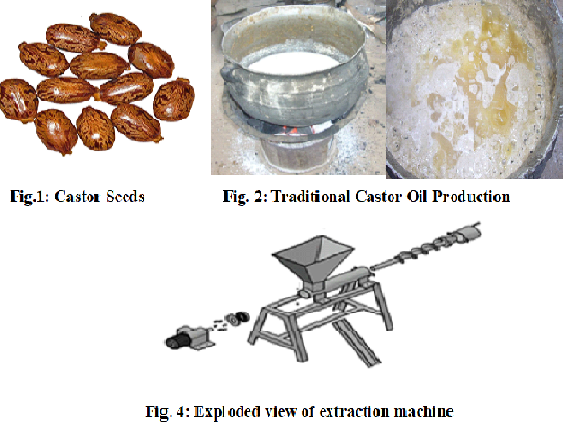

Development of a castor oil extraction machine

Keywords:

Castor seed, Oil extractor, Pre-heat, Oil waste, High qualityAbstract

A variety of processes, drawbacks, and wastes associated with existing techniques of castor seed oil extraction, specifically the traditional method, lower the quantity, quality, and pace of castor oil production. This paper built an efficient and high-quality castor seed oil extraction machine and contrasted its performance with common manufacturing method. A castor oil extractor was designed, fabricated, and performance assessed using the continuous screw method and revolving screens, powered by 4 horsepower pumps. Within the designed apparatus of 10 kg capacity, a range of 0.78–2.58 kg of castor beans was heated for 8 and 15 minutes and then crushed for 10 minutes in separate sessions. The initial run produced an average of 0.072 kg of unclean and moist cake. After 15 minutes of device preheating, an average of 1.16 kg and 0.9 kg of virgin oil and baked cake came out, respectively. Preheating the machine improved its oil extraction output by 61%. Relative to the lengthy, dirty old typical, the newly created technology results in better extraction operations, less castor seed oil waste, and a faster production period. The developed machine results in more castor oil produced, fewer toxicity hazards, time savings, and environmental hygiene maintenance.