Aerodynamic and performance analysis of an Axial flow compressor

Keywords:

Axial Flow Compressor, Aerodynamic and Performance Analysis, Diffusion Factor, GE Frame 9E Compressor.Abstract

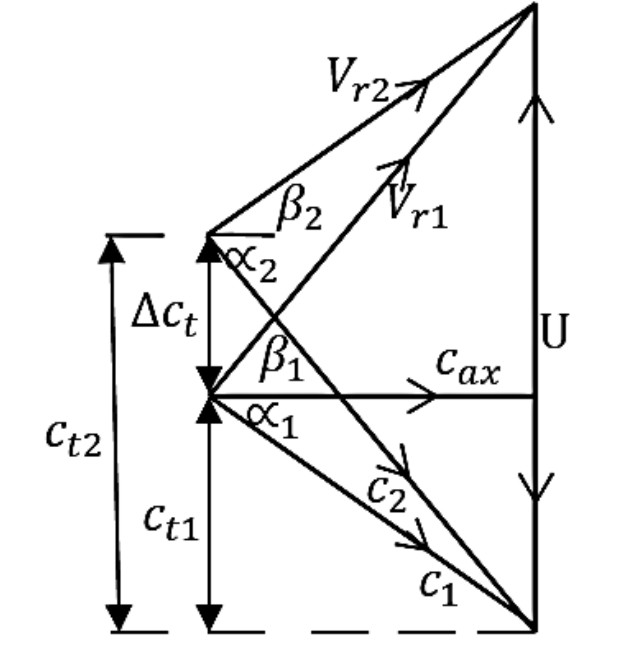

This study intends to determine performance and aerodynamic details on the GE Frame 9E compressor unit. The objectives are to model the axial compressor performance, flow behaviour and degree of reaction distribution with Simulink. A Simulink model of GE Frame 9E compressor was used; design parameters were applied to the model; performance simulation and analysis were carried out. Results showed diffusion factor, flow, temperature, pressure coefficients and stage efficiency of 0.36 to 0.4, 0.61, 0.33, 0.3, and 0.92 respectively, and degree of reaction was between 0.67 and 0.55. At pitch-chord ratio of 0.4, diffusion factor was 0.38 at last stage. At a rotor inlet flow angle of 15o, degree of reaction and diffusion factor were from 0.4 to 0.69 and 0.46 to 0.37 accordingly as engine speed increased from 40rps to 60rps. GE Frame 9E compressor maintained high stage efficiency, and flow, temperature, pressure coefficients and diffusion factor were satisfactory. Diffusion factor decreased with reduced pitch-chord ratio, but at higher inlet flow angles diffusion factor was increased and degree of reaction was reduced, and vice versa at higher engine speed. This study has brought to the fore the performance details, the distribution of the diffusion factor and degree of reaction of a GE Frame 9E axial flow compressor, and the influence of engine speed and rotor inlet flow angle on them.