Synthesized activated rice husk ash as a heterogeneous catalyst for biodiesel production using waste cooking oil

Keywords:

Activated Rice Husk Ash, Waste Cooking Oil, Calcination, Transesterification, Optimization, Biodiesel ProductionAbstract

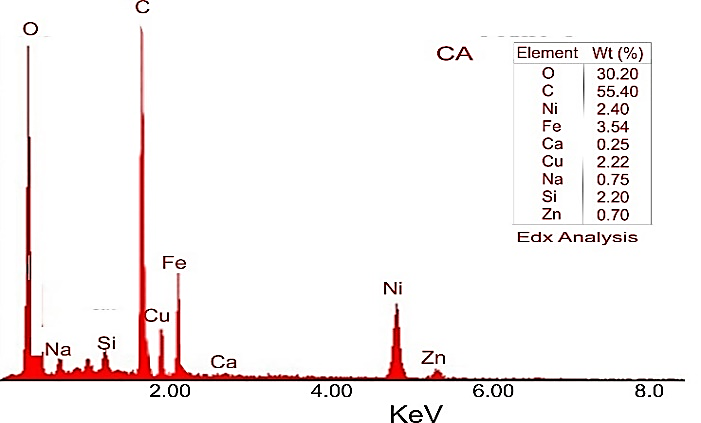

Biodiesel has been globally recognized as the right replacement to reduce the effects of fossil fuel usage due to its renewability and eco-friendly nature. The cost of synthesizing biodiesel though transesterification process can be significantly reduced by using waste feedstock materials such as waste cooking oil with calcined rice husk ash activated using sodium hydroxide salt solution catalyst which forms the basis of this present study. A direct transesterification process was adopted in this study with the reduction of the free fatty acid value of the waste oil from 6.61 to a satisfactory ASTM value of 1.12 through multiple hot water washing and filtering. The characteristic study of activated rice husk ash using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), Scanning electron microscopy (SEM), confirmed that the produced catalyst contains sodium silicate and undergo some morphological changes after impregnation with sodium hydroxide solution at a calcination temperature of 500 oC for 4 h. The process parameters were optimized using one factor at a time (OFAT) to obtain the optimal yield of 86 % at the optimal conditions of methanol to oil molar ratio (9:1), process temperature (55 oC), catalyst concentration (3.0 wt%), agitation speed (300 rpm) and process time (3 hrs). The characteristic properties of the produced biodiesel were determined using ASTM methods and obtained properties complied with the ASTM standards.