Synthesis of Low-cost Ceramic microfiltration membrane with sawdust as pore former for brewery water purification

Keywords:

Microfiltration, Nsukaolin, Response surface methodology, Strike waterAbstract

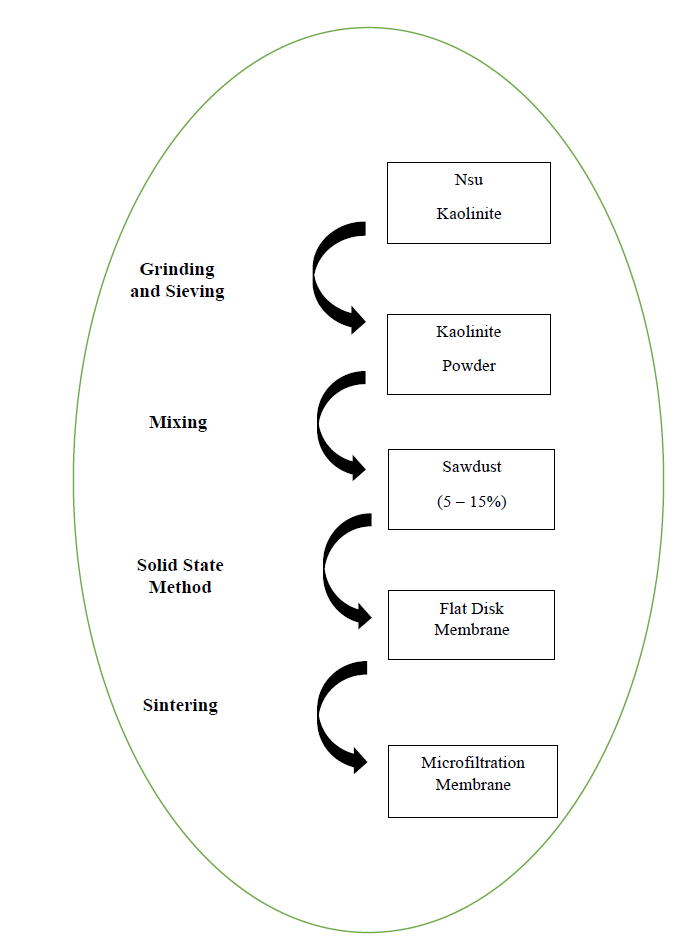

A flat microfiltration membrane was successfully developed using natural Nsu kaolinite clay and sawdust as a pore former through the solid-state method. The goal is to minimize dependence on costly imported sand and activated carbon filters for brewery water treatment. The membrane's preparation conditions, including kaolinite content, the optimal sintering conditions, including temperature and duration, were determined utilizing Response Surface Methodology (RSM) based on Box-Behnken design. The optimized membrane exhibited excellent properties, including high porosity (44.4%), permeability (1566.6 L/h/m²/bar), mechanical strength (35.97MPa), and suitable pore size (0.8332 µm). The membrane demonstrated exceptional purification performance when treating brewery borehole water, successfully eliminating turbidity, conductivity, TSS, and TDS to meet brewery quality requirements with rejection rates of 87.4%, 75%, 90%, and 75.9%, respectively. Additionally, the pH of the purified water fell within the acceptable range for brewery strike water, which tends to be neutral.