Comparative Study on the Compressive Strength of Concrete Produced Using Local Gravel from Umunya and Nkpor Gravel Deposits in Anambra State with Granite Aggregate Concrete

Keywords:

Coarse aggregate, gravel, Aggregate impact value, Aggregate crushing value, compressive strengthAbstract

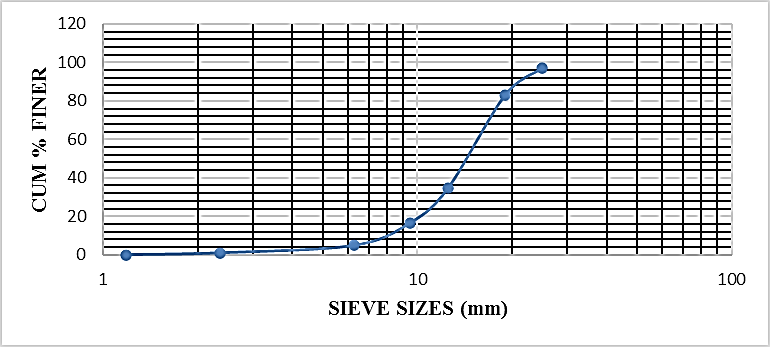

The primary aim of this research is to determine the suitability of the local gravel found in Umunya and Nkpor, Anambra state for concrete production. Properties of concrete material such as aggregate impact value (AIV) and crushing value test (ACV), sieve analysis test, specific gravity test were investigated. Slump and compressive strength test were also conducted on the concrete samples. Sieve analysis test revealed that the local gravel sourced from Nkpor and Umunya had coefficient of uniformity of 2.23 and 1.86 respectively. With AIVs of 41.05% and 43.92% the local gravels sourced from Umunya, and Nkpor showed unsatisfactory result. Similarly, the gravels sourced from Umunya and Nkpor revealed unsatisfactory result with ACVs of 32.46% and 37.96% respectively. In contrast, granite had satisfactory AIV and ACV of 33.15% and 27.52% respectively. The specific gravity test indicated satisfactory density levels for all materials used in this research. The workability test revealed a moderate slump of 46mm for the concrete made with granite aggregate. The concrete made with gravel from Umunya had a slump of 42mm while that from Nkpor had a slump of 51mm. With a compressive strength of 15.73N/mm2, 24.39N/mm2, 27.90N/mm2 and 31.01 N/mm2 at 7, 14, 21 and 28 days respectively, the gravel sourced from Umunya performed better of the two gravels gotten from Anambra state. The gravel sourced from Nkpor had a compressive strength of 14.41N/mm2, 21.76N/mm2, 23.56N/mm2 and 27.93N/mm2 at 7, 14, 21 and 28 days respectively. Granite had a compressive strength of 18.24N/mm2, 26.51N/mm2, 32.55N/mm2 and 35.02N/mm2 at 7, 14, 21 and 28 days respectively. Due to their poor performance in the ACV and AIV tests, the gravels sourced from Umunya and Nkpor are unsuitable for concrete production intended for applications subjected to wear and impact when no modification is done. However, it is suitable for conventional construction.