Experimental investigation of the effects of optimal weld time on mild steel weldment strength using expert methods

Keywords:

TIG, Mild Steel, Weld Time, RSM, ANNAbstract

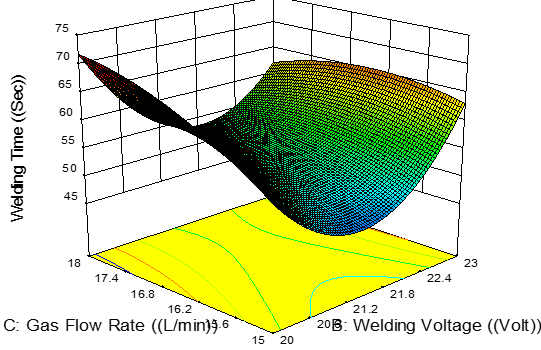

This research study aims to develop models for the optimization (minimization) of the weld time of mild steel weldment using response surface methodology and artificial neural network. The input factors used in this research study are: current, voltage, and gas flow rate. The output parameter is the weld time. The welding process used for the experimental welding is the tungsten inert gas (TIG) welding.. Weld time adequately optimized will produce a quality weld with the desired strength. The RSM analysis gave the optimal solutions for each of the input factors with current as 180.00Amps, voltage as 21.672Volts, and gas flow rate as 15.504L/min. The optimal solution for the output factor, weld time is 44.000secs. The optimum results were achieved with a desirability of 83.62%. Analysis of variance results indicated that gas flow rate input factor has the most significant effect on the output variable under consideration. The artificial neural network predicted an optimal solution for the weld time response factor as 53.71292Secs, and showed an overall strong correlation (R) between the input factors and the output parameter to be 99.893%. Therefore, the models are recommended to be used for design and application. However, the optimal solution of the artificial neural network analyses will produce a better and more quality weld because of its higher Regression (R) value, and thus, suggested for practical application and systematic decision making.