Sustainable Bio-Aviation Fuel Production from Biobased Oil: A Novel Hydrogen-Free Biorefinery Approach

Keywords:

Biorefinery, Bio-aviation fuel, Activated carbon catalyst, Kinetics and Thermodynamics, Jatropha oilAbstract

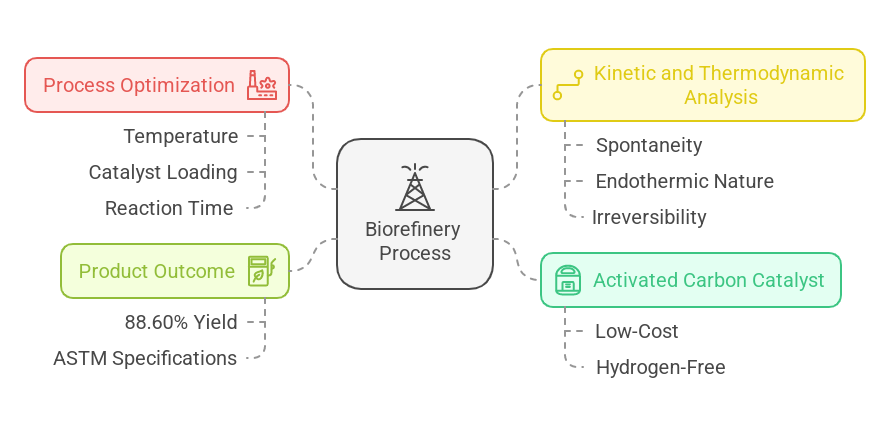

This study investigates a novel biorefinery strategy for the sustainable production of bio-aviation fuel. The process involves a single-step, hydrogen-free simultaneous (heterogeneous) fluid catalytic conversion and recovery (SFCCR) of Jatropha seed oil (JO) using a low-cost oxalic acid functionalized-activated carbon catalyst from rice husk. To optimize the process, response-surface-methodology (RSM) was employed using a central composite rotatable design (CCRD). The study examined the influence of temperature, catalyst loading, and reaction time on the SFCCR process and evaluated its kinetics and thermodynamics. A maximum bio-aviation fuel yield of 88.60% was achieved under optimized conditions: 394.69 °C, 4.67 g catalyst loading, and 62.25 minutes reaction time. Kinetic analysis revealed that the SFCCR process best fit a pseudo-second-order model, characterized by a high coefficient of determination (R² = 0.96), adjusted R² (0.94), and low values for the sum of squares of errors (SSE = 4.75) and root mean squared error (RMSE = 1.0). Thermodynamic analysis yielded a negative Gibbs free energy (∆G = -13.66 kJ/mol), indicating a spontaneous reaction. Furthermore, the process was found to be endothermic (∆H = 389.32 kJ/mol) and irreversible (∆S = 0.61 kJ/mol). The resulting bio-aviation fuel, composed of hydrocarbons in the C9-C16 range, met ASTM specifications for aviation turbine fuel. This study demonstrates the potential of this hydrogen-free, single-step catalytic process for sustainable bio-aviation fuel production, highlighting the viability of utilizing functionalized activated carbon catalysts in biorefinery systems.