Investigation of Hydrocarbon Associated Gas Separation in a Vertical Vessel: A Steady-State and Dynamic Simulation Using Aspen Hysys

Keywords:

Petroleum; associate gas stream; Aspen HYSYS®; simulation; Steady state; DynamicAbstract

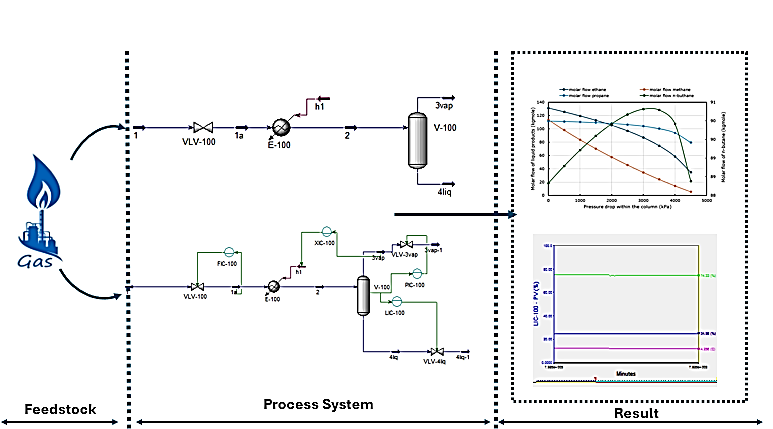

The global push for decarbonization has amplified the need for the sustainable utilization of conventional fossil fuels. Associated gas, a low-value byproduct of petroleum production frequently flared or vented, has gained attention as a viable solution for reducing the carbon footprint of petroleum operations. When converted into valuable products, it offers the potential to enhance the sustainability and efficiency of production systems. This study presents the separation of associated gas (methane, ethane, propane and n-butane) into various proportions in liquid and gas product streams using Aspen HYSYS® software 11 under both steady state and dynamic conditions. The flowsheet was developed using a Pen-Robinson thermodynamic fluid package with a stream flow rate of 1000 kgmole/h charged into a vertical separator. The effect of pressure drop within the column on the product stream separation was investigated in the steady state. The system responses for step changes in molar flow, vessel liquid level, vessel pressure and methane fraction in the vapour product stream were examined in the dynamic simulation using a proportional-integral-derivative (PID) controller. The steady-state result showed that the pressure drop within the column significantly affects separation efficiency, with methane showing the steepest decline in molar flow within the liquid stream product. The n-butane exhibited a non-linear optimal range, while the ethane and propane decreased steadily. In the dynamic state, the system can handle flow rates between 900–1100 kgmole/h, liquid levels of 20–30%, and pressures of 47–49 bar, while maintaining methane composition between 55–65%. The system attained stability by decreasing the rise time and reducing the overshoot and settling time of the flow controller. The Pressure controller has the highest proportional gain (1.00) for a strong response to changes, while methane composition control has the smallest integral time (0.07), indicating rapid adjustments for deviations. This study effectively describes the steady state and the dynamic behaviours of the associated gas separation system, providing critical information for process optimization and control.