Modeling and Optimization of Fibreboard Production from Corn Husk using Response Surface Methodology

Keywords:

Corn-husk fiberboard; RSM; Mechanical properties; Optimization; Sustainable materialsAbstract

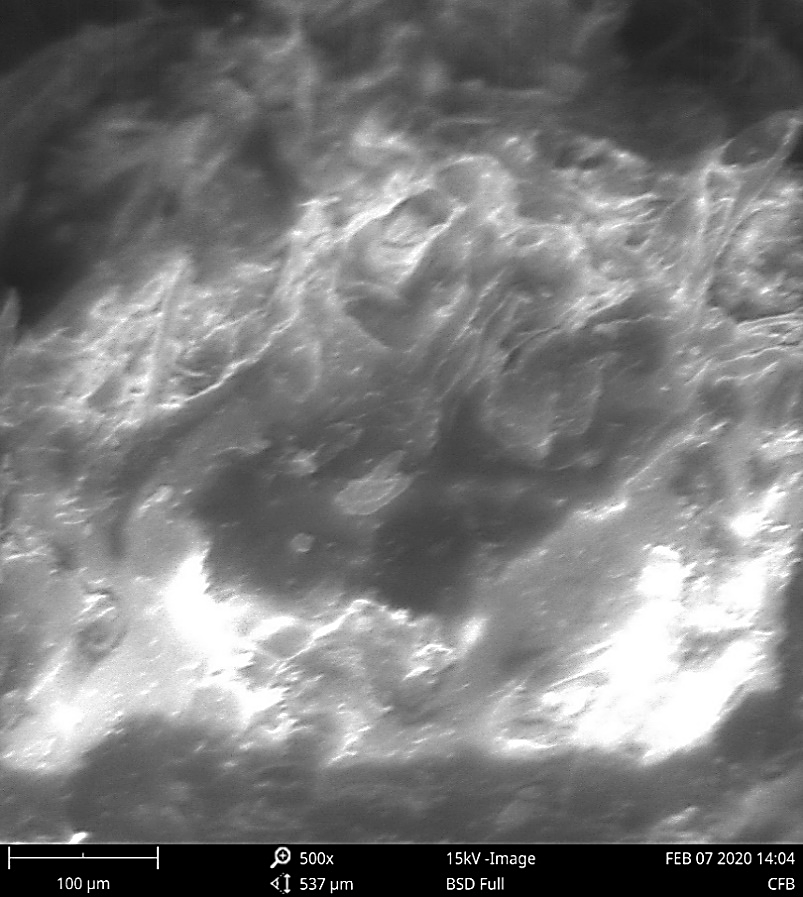

This study optimizes the production of fiberboard from corn husk using Response Surface Methodology (RSM). RSM was employed to identify the optimal conditions for achieving superior strength and durability. The effect of key process parameters such as Fiber/rLDPE ratio, press time, press temperature, and press pressure, on the mechanical properties of the fiberboard was assessed. Instrumental analyses, including Scanning Electron Microscopy (SEM) and Thermogravimetric Analysis (TGA), were performed to assess the fiberboard's microstructure and thermal stability. The optimal process parameters were a Fiber/rLDPE ratio of 12.5, press time of 7 minutes, press temperature of 190°C, and press pressure of 10 MPa. Under these conditions, the Modulus of Rupture (MOR) reached 41.86 MPa, Modulus of Elasticity (MOE) was 2718.8 MPa, and Internal Bond (IB) strength was 1.72 MPa. SEM revealed a uniform surface structure with good interfacial bonding, while TGA indicated high thermal stability with a weight loss of 15% at 350°C. The fiberboard had a density of 844 kg/m³ and exhibited minimal thickness swelling (4.76%) and water absorption (4.93%). These results show that corn husk fiberboard meets industry standards for strength, durability, and sustainability, making it a viable and eco-friendly alternative to conventional wood-based panels for industrial applications.