Parametric determination of Ethanol yield from cocoyam and Cassava Peel Mix

Keywords:

Ethanol yield, Cassava peel, Wild cocoyam, Fermentation, Biofuel, Optimization, Response Surface MethodologyAbstract

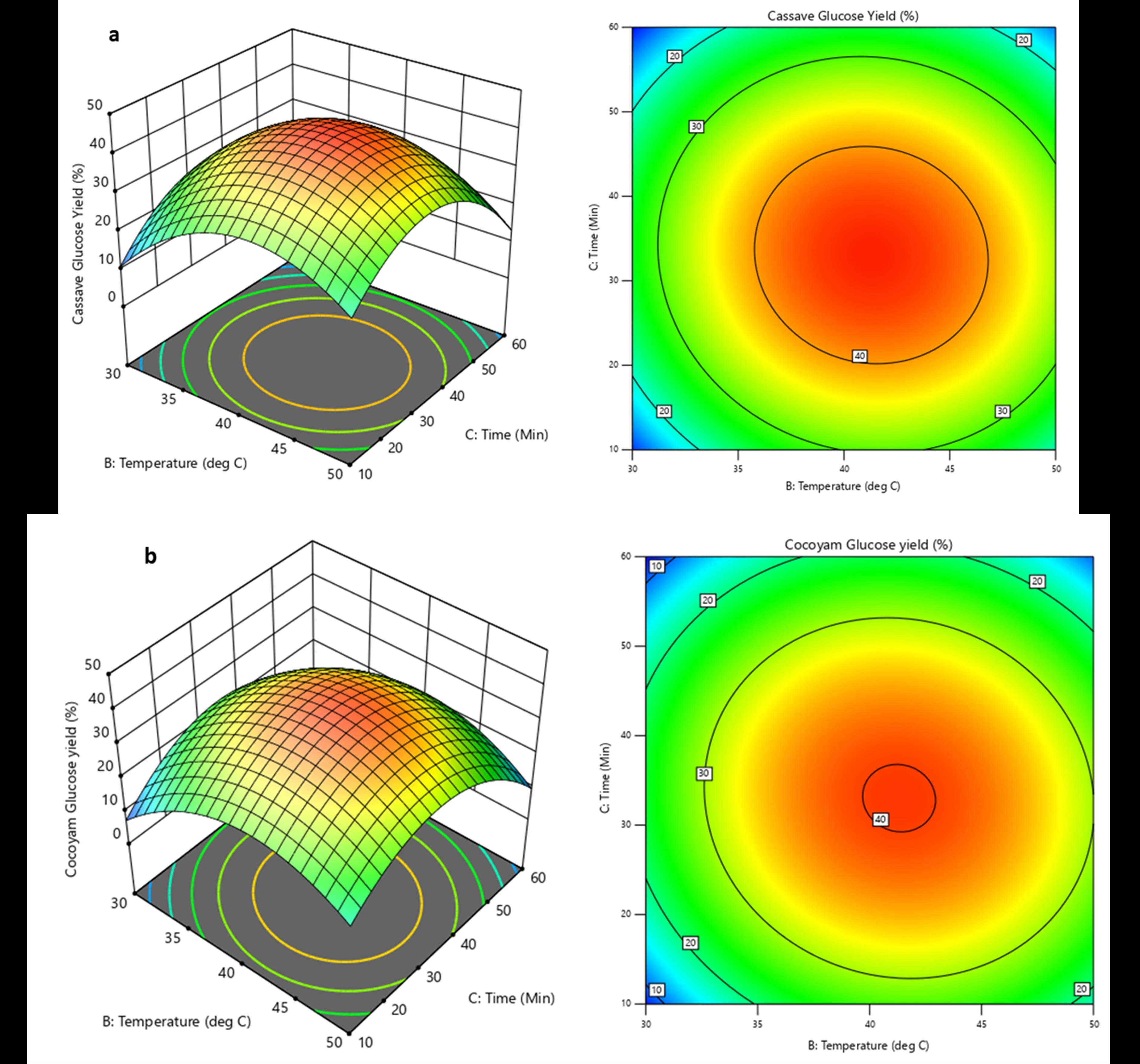

The rising global demand towards sustainable energy has created a need for research into alternative biofuels. This study was carried out on parametric determination of ethanol yield from substrate of wild cocoyam (Colocasia esculenta) and cassava peel (Manihot esculenta) in mixture. This study used Box-Behnken Design (BBD) to opt for protein isolation from Cassava Peel Cellulose (CPC) and starch of Wild Cocoyam (WCS), were evaluated as glucose and ethanol. Carbohydrate composition of the substrates was determined by proximate analysis which revealed that cassava peel was higher in carbohydrate (87.69%) than wild cocoyam (77.37%) and an indication that both are good feedstock for bioethanol production. The Central Composite Design (CCD) was used for the optimization of fermentation. Cassava peel cellulose range of glucose yield from 8.96% to 45.5%, whereas, wild cocoyam starch range was from 6.07% to 42.28% as glucose. Quadratic regression models provided the best fit for predicting glucose yield, with high coefficients of determination (R² = 0.9977 for cassava peel and R² = 0.9967 for wild cocoyam), confirming the significance of the process variables. Ethanol yield was determined using standard ethanol density comparisons and a specific gravity meter, and bioethanol-gasoline fuel blends (E10, E15, E20, and E25) were assessed for potential alternative fuel applications. The findings indicate that CPC glucose yield ranged from (8.96%–45.5%), while WCS glucose yield ranged from (6.07%–42.28%). A quadratic model best explained variations, with R² values of (0.9977) for CPC and (0.9967) for WCS. ANOVA results confirmed model significance (F-values: CPC—339.92, WCS—232.81; p < 0.0001). Response surface plots showed optimal glucose yields within specific design boundaries. Regression equations identified acid concentration, temperature, and time as key influencing factors, with positive coefficients enhancing yield and negative coefficients reducing it. The study concludes that agro-waste materials can be harnessed for sustainable biofuel production, with future research recommended on enzymatic hydrolysis and large-scale bioethanol production feasibility.