Preliminary Investigation of the Material Properties of Metakaolin Based Geopolymer Concrete (MKGPC) Using NaOH and Na2SiO3 as an Activator

Keywords:

Geopolymer concrete, metakaolin, workability, setting times and soundnessAbstract

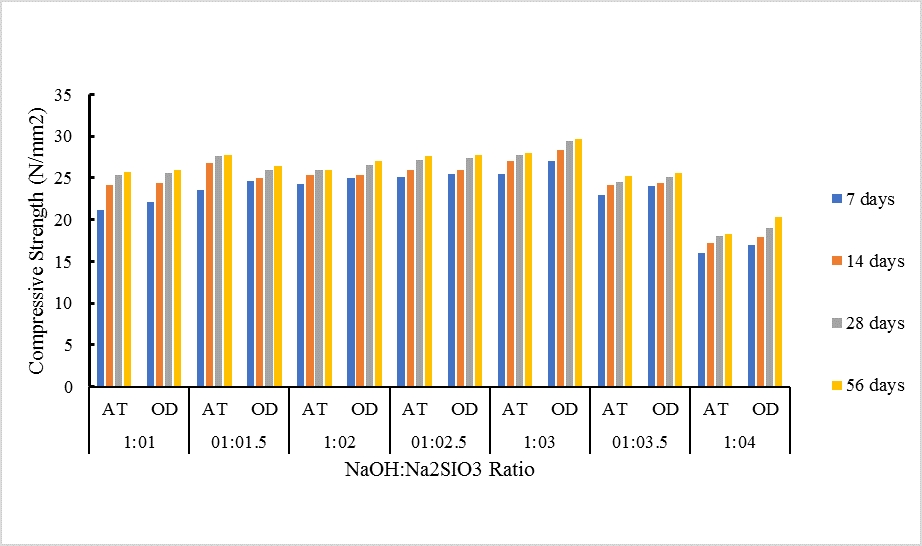

The study focus on the material properties of MKGP concrete. Metakaolin to alkaline liquid ratio (MK/AL) used was 0.8 with grade 20 concrete. The highest soundness value recorded at mix ratio 1:4 for 8M and 12M molar concentration was 1.3mm and 1.1mm respectively. Which clearly indicates that the MKGP is unsound as the value gotten was below 10mm. Also, for 8M molar concentration the initial alkaline liquid (NaOH:Na2SiO3) ratio for 1:1 and 1:4 are 48mm and 18mm and final setting time alkaline liquid ratio for 1:1 and 1:4 are 216mm and 83mm. Similarly, for 12M molar concentration the initial ALr (NaOH:Na2SiO3) for 1:1 and 1:4 are 39mm and 15mm and final setting time ALr for 1:1 and 1:4 are 175mm and 79mm. This implies that initial and final setting time decreases with decrease in NaOH content and an increase Na2SiO3 content also reduce the setting times. The highest slump value obtain for 8M and 12M concentration was 133mm and 124mm respectively at ALr 1:4. This shows that increase in molarity of NaOH decreases workability and a gain in workability was record due to increase in sodium silicate content. XRF result of metakaolin shows that Al2O3 and SiO2 content is 93.92% which indicate a good pozzolanic material. The compressive strength of the material increased as the curing age increases. More so, it was observed that for 8M and 12M molar concentration, the highest compressive strength was 28.8 N/mm2 and 29.7 N/mm2 respectively and was obtained at a mix ratio of 1:3.