Durability and Microstructural Performance of Metakaolin-based Geopolymer Concrete under Elevated Temperature Exposure

Keywords:

purposes. Geopolymer concrete, elevated temperature, metakaolin, density, XRD, durabilityAbstract

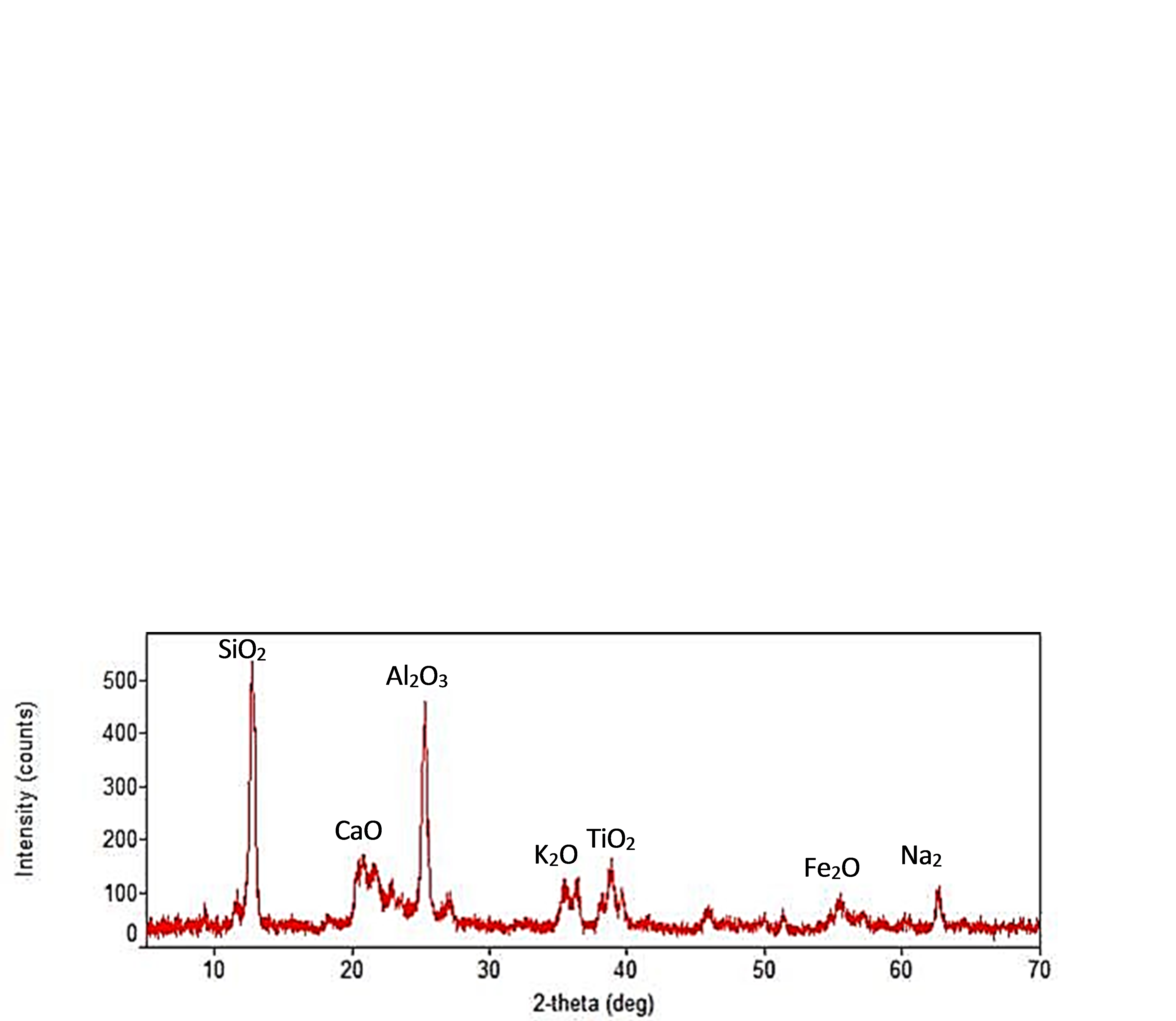

Concrete materials exposed to harsh environment usually experience changes in the microstructure and physical appearance. Geopolymer concrete specimens of grade 20 N/mm2 was targeted at a mix ratio 1:2:4 for metakaolin, fine and coarse aggregate respectively and the alkaline liquid (NaOH:Na2SiO3) which key start the geopolymerisation process was varied from 1:1 to 1:4. The water content of the Na2SiO3 was found to be 40.80 % with a pH value of 12.8 and oxide value of 3.89.This implies that, the commercial sodium silicate use in this study exhibited acceptable pH and silica modulus for geopolymerization. The XRD pattern of the unheated (MKGPC) sample exhibits the characteristic peaks of conventional metakaolinite functions at Bragg’s angles of 11.44, 12.72, 20.45, 25.28, 27.02, 35.88, 38.83, 55.58 and 62.37°. The peak at 12.72° was due to present of the undisturbed crystalline silica in the analyzed sample. The XRD pattern shows a highly amorphous characterization with no sharp peaks for the heated sample. The SEM micrograph shows some changes in the microstructure as the sample transform from crystalline to amorphous for the heated geopolymer concrete. The sample was inserted in a furnace and the temperature was elevated from100OC to 1400OC at a varying period ranging from 2 to 8 hours in accordance with BS EN 12390-2. The optimum mix ratio of 1:3 gave the highest compressive strength, for 12M concentration of (NaOH), there was no significant changes in the compressive strength of 30 N/mm2 obtained at 200 0C until at a temperature of 5000C after which it continue to drop. However, at lower and higher temperature ranging from 100OC to 400OC and 1000OC to 1400OC respectively, the compressive strength was constant as it shows no significant effect even at hourly increase in elevated temperature ranging from 2hrs to 8 hours. More so, the density loss was constant at lower temperature and decreases as the temperature increases.