Adaptive Neuro-Fuzzy Inference System Based Statistical Optimization and Chemical Reaction Kinetics Modeling of Waste Cooking Oil Transesterification

Keywords:

ANFIS; Biodiesel; Waste cooking oil; Reaction kinetics; OptimizationAbstract

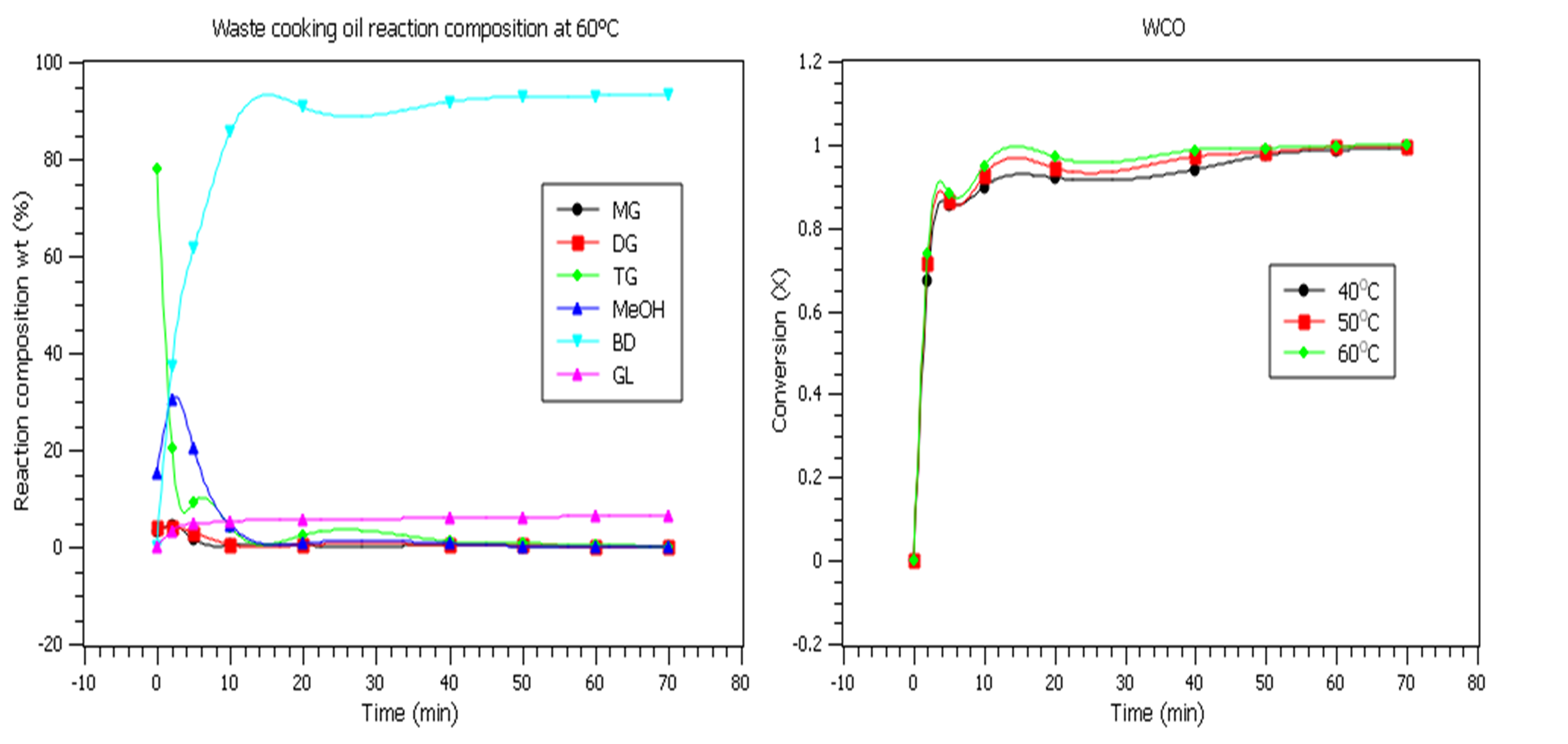

Investigation into the application of adaptive neuro-fuzzy inference system (ANFIS) and the chemical kinetics modeling of the transesterification process for optimal base methanolysis of waste cooking oil (WCO) were carried out. Statistical performance indicators of ANFIS-GA technique were employed in determining a better predictive capability and economic conditions for the optimal production of fatty acid methyl esters from WCO obtained from refined palm olein. Modeling of various temperature effects on the transesterification kinetic reaction processes were used to obtain the rate constant and kinetics order of reaction. GC, AOAC, ASTM D standard methods were applied in the evaluation of the biodiesel fuel quality. The statistical indices that gave rise to WCOB optimal yield of 87.34% were (coefficient of determination, R2 = 0.9550, mean square error, MSE = 0.13657, sum of square error, SSE = 4.3734 and root mean square error, RMSE = 0.3697) at the integrated ANFIS-GA process input variables (methanol/oil ratio 3.97, reaction temp 52oC, catalyst loading 1.53 wt%, stirring speed 300rpm and reaction time 56 min). The transesterification kinetics order of the modeled process revealed first order with activation energy value and rate constant of 18.458kJ/mol and 0.1140 min−1 respectively. Application of the waste feedstock in biodiesel production is found to be viable with satisfied fuel quality of standard specification.