Artificial Intelligence and Machine learning - Driven Real-Time on Vibration Signal Analysis in Automotive Engines

Keywords:

Artificial Intelligence, Machine Learning, Real-Time, Vibration Signal Analysis and Automotive EnginesAbstract

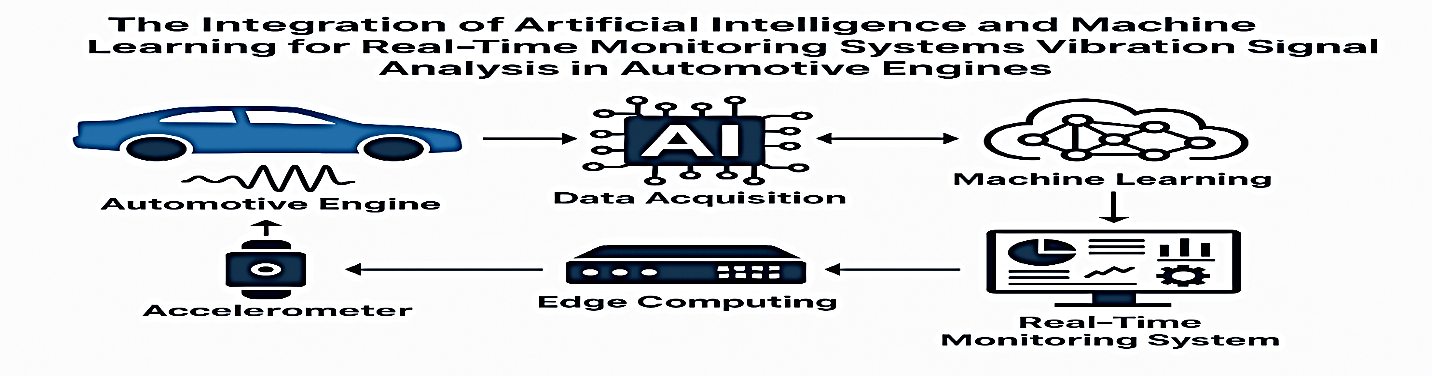

This research presents an open-source Python-based framework designed for real-time analysis of engine vibration signals using artificial intelligence (AI) and machine learning (ML) techniques. Unlike conventional approaches that depend heavily on manual feature extraction and offline diagnostics, the proposed system employs automated processing to enable immediate fault detection. Advanced models, including deep convolutional neural networks (CNNs), support vector machines (SVMs), and random forests (RFs), are utilized to facilitate rapid and accurate diagnostics. Vibration data were gathered via piezoelectric sensors attached to engine blocks operating under controlled conditions, resulting in a dataset comprising approximately 1.2 million data points across diverse engine cycles. Signal preprocessing and feature extraction were conducted using MATLAB R2024a, while model training and inference were implemented in real time using Python 3.10, with support from TensorFlow 2.11, PyTorch 2.0, and scikit-learn 1.2.3. Platforms such as VibroSight and DASYLab 2023 were employed for data acquisition, signal visualization, and automation of the diagnostic workflow. Statistical analyses, including one-way ANOVA and independent t-tests, revealed that a hybrid CNN–RF model (referred to as Hybrid Design 4) attained the highest mean diagnostic accuracy at 90.4%, significantly outperforming a traditional threshold-based model which achieved 78.5%. The reliability and statistical significance of these results were confirmed through 95% confidence intervals and p-values below 0.05. These findings underscore the potential of AI/ML integration in real-time vibration monitoring systems, promoting the development of predictive maintenance (PdM) solutions and enhancing the reliability of next-generation autonomous vehicle engines