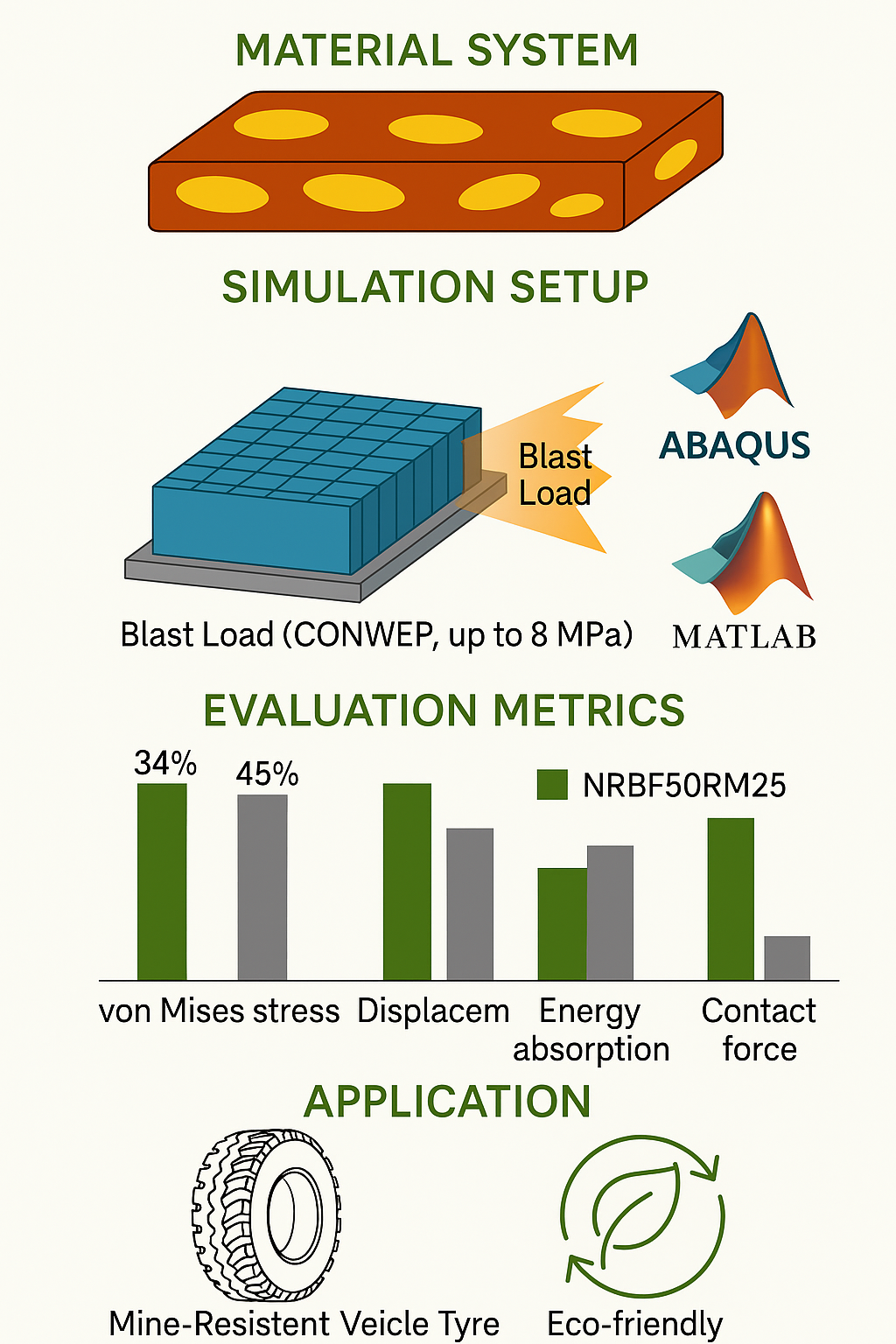

Finite element modeling and simulation of banana fiber-reinforced natural rubber composites for mine-resistant tyres

Keywords:

Banana Fiber, Natural Rubber, Finite Element Analysis, ABAQUS, Blast Simulation, Mine-Resistant TyresAbstract

This study investigates the potential of banana fiber-reinforced natural rubber (NR/BF) composites for enhancing the blast resistance of vehicle tyres used in defense applications. Conventional tyre materials often exhibit poor performance under explosive loading conditions, leading to catastrophic failures in mine-affected environments. To address this limitation, finite element modeling was employed using ABAQUS/Explicit to simulate the dynamic response of various NR/BF formulations subjected to blast pressures up to 8 MPa. Flat sheet specimens of the composites were modeled as hyperelastic materials using a Mooney-Rivlin formulation, with material constants derived from prior tensile testing. The CONWEP method was applied to replicate surface blast effects, and key simulation metrics, including von Mises stress, displacement, strain energy, and contact force, were extracted and analyzed using MATLAB. Among the tested formulations, NRBF50RM25 exhibited superior performance, achieving a 34% reduction in peak stress and 45% lower displacement compared to neat rubber, along with enhanced energy dissipation characteristics. These findings highlight the potential of NR/BF composites as sustainable and effective materials for improving blast resilience in tyre design, supporting further development toward next-generation mine-resistant vehicle systems.